FT25BS2-R

ENGLISH

ISFT25BS2REU_07_07.doc

1. General

Description

The FT25B photocells are fitted with a transmitter that can be powered by two 3V6 2.7Ah lithium Thionyl chloride batteries or with an external 12/24V

AC/DC power supply, selectable with a jumper.

The optical unit (emitter diode + lens) of the transmitter and of the receiver can be oriented in three different directions so it can be adapted to

different installation situations.

The photocell has two terminals for the connection of a free contact of an external safety device (safety edge) and two terminals for the connection of

a resistive edge. The photocell is particularly suited for use on sliding gates, mounted on the mobile part it can be connected to a wire or resistive

safety edge, without having to lay cables or use re-wind cables.

The battery life-span is more than 15 months.

In compliance with European reference standards (Electromagnetic Compatibility 89/336/CEE).

2.

Main technical features

Power supply Transmitter

2 3V6 2.7Ah Lithium Thionyl chloride batteries

Alternatively 12 - 24 V AC/DC

Power supply Receiver

12 -24 V AC/DC

Consumption Transmitter

< 500 µA

Consumption Receiver

30 mA

Container ABS

Dimensions/weight

110 x 50 x 25 mm 200g

Protection rating

IP 45

Infra-red wavelength

950 nm

Relay contact range

0.5 A @ 24 V AC/DC

Infra-red beam range

25 m nominal (8 m outdoor )

Operating temperature

-20 +55° C

Intervention time with triggering of

photocell beam

< 40 ms

Intervention time with triggering of

safety edge connected to terminal

strip

< 60 ms

Reset time

< 150 ms

3.

Receiver terminal strip

1

+V

2

- V

Power supply 12 - 24 V AC/DC

3

N.C./N.O.

4

C

Relay contact normally open or closed depending on

NO/NC selection jumper

5

LOW BAT

6

LOW BAT

Flat battery Normally open contact

4.

Transmitter terminal strip

1

+12 - +24 V AC/DC

Power supply 12 - 24 V AC/DC

2

0 V

Common power supply

3

EDGE

4

EDGE

Terminal for safety edge free contact

(j

ump if not used)

5

EDGE 8K2

6

EDGE 8K2

Terminal for 8K2 resistive edge

(DON’T j

ump if not used)

5. Installation

-

Fix the photocell using the supplied drilling template (fig. 2)

-

Make connections as indicated in the previous paragraphs and

select the transmitter power supply with the specific jumper (J1,

Fig. 1B):

POSITION A: external power supply 12-24 V AC/DC

POSITION B: battery powered

-

Select the same operating frequency on the receiver and on

the transmitter with the specific jumpers (J2, fig 1A & 1B):

Frequency 1: Jumper disabled

Frequency 2: Jumper enabled

-

Connect to the specific terminal strip (terminals 3 & 4, Fig. 1B)

the safety edge or external safety device contact to the

transmitter.

If this option is not used, jump terminals 3 and

4.

-

Connect to the specific terminal strip (terminals 5 & 6, Fig. 1B)

the contacts of the 8K2 resistive edge external to the

transmitter.

If this option is not used, do NOT jump

terminals 5 and 6.

-

Select on the receiver the logic of the NO or NC output contact

with jumper J3.

-

Position on the transmitter the probe in the position from the

three possibilities most suitable to the alignment.

-

Align the beam to the receiver by adjusting the specific fixing

screws “A” (fig. 2) supplied, both on the receiver and the

transmitter.

-

With a voltmeter, measure the tension value on the receiver

test-point. (Fig. 2). This value varies according to various

parameters, among which the distance between the photocells.

The higher the tension value on the test-point the better is the

alignment. The ideal measure should be between 0.5 and 0.6

VDC.

-

Check that the interruption of the infra-red beam causes the

opening of the normally closed contact of the relay on the

receiver and the lighting up of the red LED.

6.

Flat battery signal

The flat battery situation is signalled optically by the transmitter to

the receiver.

The receiver closes the free LOW BAT contact available in the

terminal strip and activates an intermittent buzzer.

The flat battery indication is given one week before the battery is

completely flat.

Once the batteries have been replaced, switch the receiver OFF

then back ON to deactivate the LOWBAT contact and the buzzer.

However, this will happen automatically after 15 minutes.

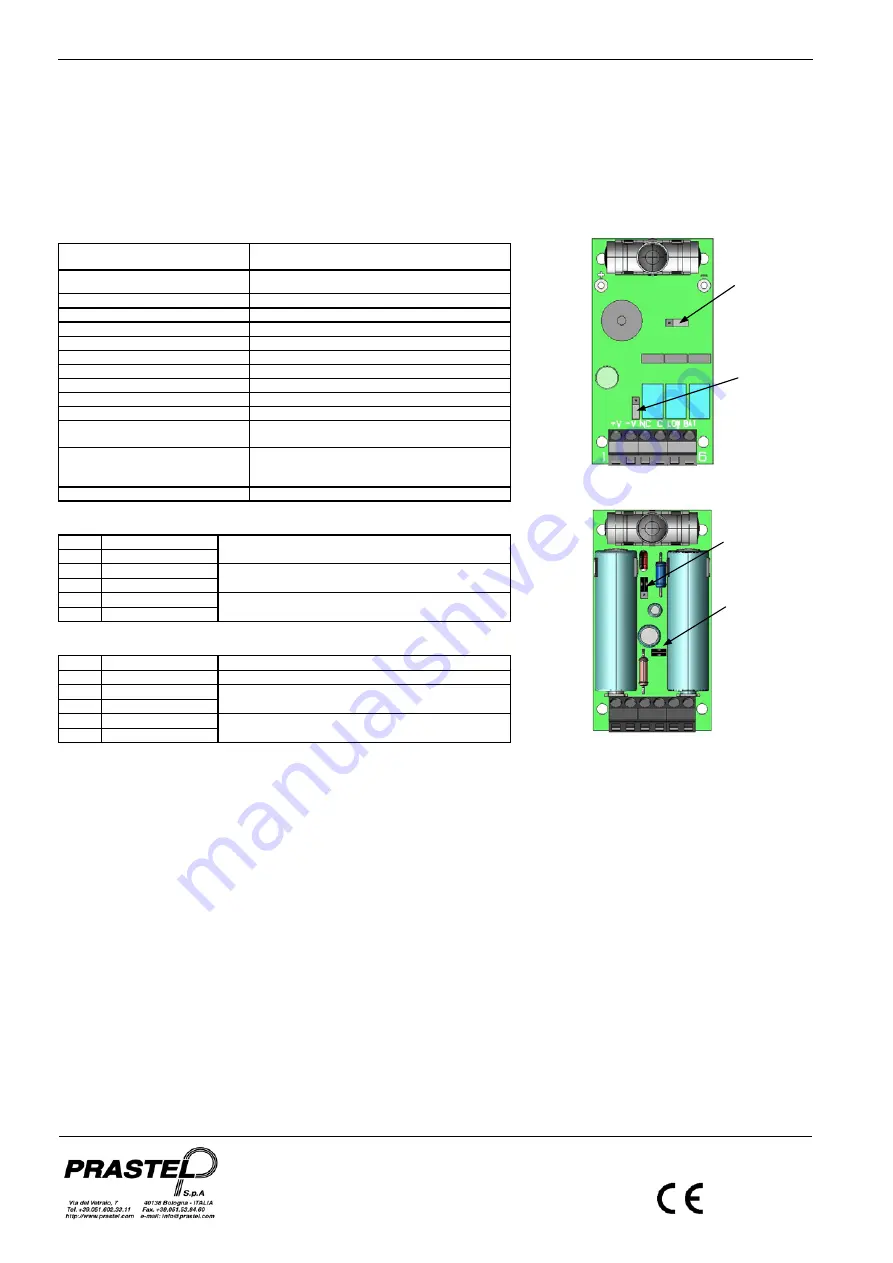

J1: Power supply

selection

Fig. 1B

(TX)

B

A

J2: Frequency

Selection

1 2 3 4 5 6

Fig. 1A

(RX.)

J2: Frequency

Selection

J3: NO/NC

contact selection

1 2 3 4 5 6

Содержание FT25B Series

Страница 4: ...TEST POINT 0 5 0 6 VDC TX RX TX ...