We remind you that packing material (wood, nails, paper, cello-

phane, metal staples, adhesive tape, straps, ropes, etc.) may cause

cuts or wounds and should be handled with care. These must be

removed with appropriate tolls and should not be left in the care

of irresponsible people ( e.g. Children); the same applies to the

un-packing tools (scissors, hammers, pliers, knives, etc..).

On specific request, Powr-Flite will pack the machines appropri-

ately but this does not eliminate the above safety notes.

During movement, suspended loads made up of machine compo-

nents or parts represent a collision, risk, it is the responsibility of

the customer to highlight this danger.

WARNING:

before attempting to adjust or prepare the machine

or to fill the tanks, make sure that the power supply is discon-

nected.

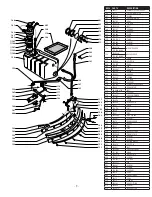

Solution Tank

: The detergent tank is positioned underneath

the upper cover at the front of the ma-chine with the filter hole

M1

easily accessible for easy refilling. Before filling the tank with

correctly diluted detergent, empty the waste collection tank as

described in the following paragraph; obviously this step is not

required for the first time of filling. The capacity of the solution

tank is 17 gal. only use the quantities and dilution recommended

by the detergent supplier and use only non-foaming detergents. If

foam is created, use a defoaming chemical in recovery tank.

Recovery Tank:

The waste tank should be emptied (preferably

after each use) so as not to let the dirt settle; to do this, remove

the cap covering the drain tube

M2

which is held in place by a

retaining spring, and put in a position so that it drains. Always

abide by the environmental regulations of the country where the

machine is used.

Squeegee Blade:

The floor squeegee serves to finish the drying

operation and it is very important to ensure it is in the correct

position: lower the squeegee to its working position using the

foot pedal

M3

; level the squeegee using the knobs

M4

so that the

black rubber strip is approximately 1 mm above the floor.

The remaining rubber strips must wipe the floor with a certain

amount of pressure; after the first few hours of operation the

rubber squeegees adapt themselves to the inclinations and the

drying action improves. The pressure of the squeegees on the

floor is regulated by pressing the knob.

When cleaning shiny or smooth floors and when there are holes

(joins between tiles) it is advisable not to use the rear (lowest)

rubber squeegee.

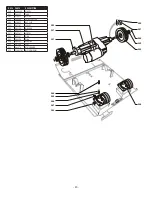

Installing and recharging the batteries: The batteries are

supplied separately and are located in the appropriate com-

partment underneath the cover; apply a coating of grease (e.g.

Vaseline) to the terminals; connect the batteries as shown in

diagram 1; make sure the terminals are securely tightened. The

battery charger should be set up in the area where it is planned

to leave the machine for recharging. Use the cable supplied to

- 5 -

Содержание PAS20DX

Страница 12: ......

Страница 15: ......

Страница 16: ...A Tacony Company 3101 Wichita Court Ft Worth TX 76140 1755...