14

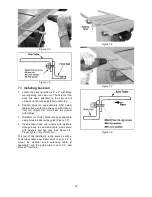

Figure 7-4

Figure 7-5

7.3

Installing back rail

1. Locate the back rail which is 2" x 2" with holes

running along one side only. The height of the

back rail when attached to the saw is not

critical, but it should be parallel to table top.

2. Position back rail approximately 9/16" below

table surface, with the ends even with those of

front rail (Figure 7-6). Hold back rail to saw

with clamps.

3. Drill 9mm (or 11/32”) holes into lip of saw table

using holes in back rail as guide (Figure 7-7).

4. Insert socket head cap screws with washers

through back rail and saw table, and secure

with washers and hex nuts. See Figure 7-8.

Finger-tighten only at this time

.

The rest of the installation is the same as with a

Powermatic table saw. Refer back to

sect. 6.4

to

mount the optional wood extension table (if

applicable) and the guide tube in

sect. 6.5

, and

proceed from there.

Figure 7-6

Figure 7-7

Figure 7-8