8

RECEIVING

Remove the lathe from the shipping container and

check for damage. Report any damage to your

distributor immediately. Accessories are packaged in

a separate carton which will be on the shelf of the

machine stand. Clean protective coating from the bed,

spindles, work rest and face plate with kerosene or a

good commercial solvent. Read the instruction manual

thoroughly for assembly, maintenance, operation and

safety instructions.

INSTALLATION

Install the four leveling screws in the legs, adjust to a

stable position and tighten the jam nuts to lock in

place.

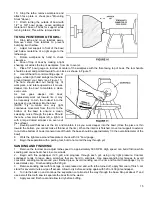

Insert the guard support rod in the guard mounting

bracket at the rear of the headstock. Position a

locking collar on each side of the mounting bracket so

that the lock pin lines up with the holes in the guard

pivot rod, one for guard position and one for load

position. The spring loaded lock pin will hold the

guard in each position.

Power Connection

The lathe will operate on single phase or three phase

230 volt power supply. A three wire pigtail for use on

230 volt single phase power is attached to the inverter

and may be hard wired to the power source or

connected to a receptacle plug. Connect the 230 volt

supply to the black and white leads and ground the

green lead.

If three phase power is used, it will be necessary to

replace the pigtail wire with a 12/4 wire and connect

the three hot leads to the inverter at R, S and T as

shown in the wiring diagram. Always connect the

ground lead.

Before connecting to the power source make sure the

on/off switch is in the off position and turn the speed

dial counterclockwise. If the switch is in the on

position when the power is connected, the inverter will

trip out. If this happens, disconnect power, turn switch

off, wait 30 seconds and then reconnect power.

NOTICE: IF THERE IS A POWER OUTAGE WHILE

OPERATING THE LATHE, TURN THE SWITCH TO

THE OFF POSITION, DISCONNECT POWER

SOURCE, WAIT 30 SECONDS THEN RECONNECT

POWER SOURCE AND RESUME NORMAL

OPERATION.

Inverter Drive System

The model 4224 lathe utilizes the latest technology in

A.C. inverter drives to provide infinitely variable

spindle speeds. The inverter controls the speed of the

motor by varing the frequency of the voltage supplied

to the motor. The inverter provides an acceleration

ramp that eliminates the shock of normal across the

line starting. Also a braking feature eliminates long

coasting periods when the lathe is turned off.

The 3 HP motor is specially designed for use with

inverter drives, and is balanced to reduce noise and

minimize vibration.

The A.C. Inverter does not require any programming,

it is pre-programmed from the factory.

The buttons

on the face of the inverter should never be pushed

at any time.

Use only the controls on the front of the

headstock.

MAINTENANCE

Maintenance on the 4224 lathe should be performed

at periodic intervals to ensure that the machine is in

proper working order, that all fasteners are tight, and

the machine is in adjustment. The more use the

machine is subjected to, the more often it should be

inspected and maintained. Inspection and

maintenance should be performed at least twice a

year.

WARNING:

To prevent accidental starting or

electrical shock, disconnect machine from

power source before performing any

maintenance.

Periodic cleaning of the lathe is important to keep the

lathe in proper working order. The lathe bed should

be cleaned and oiled periodically so that headstock,

tailstock, and tool support will slide properly. With air

hose periodically blow out headstock to keep saw

dust and chips from collecting on belt and sheaves,

and blow off dust and chips that collect on inverter

(DO NOT DISASSEMBLE INVERTER TO CLEAN).

ADJUSTMENTS

Belt Adjustment

The drive belt sheaves are initally aligned at the

factory, but if any service is performed that affects

their alignment it is very important that they be

realigned. To realign them, loosen the two set screws

on the spindle sheave and slide it in the proper

position. Use of a straight edge along the edge of both

sheaves will simplify the positioning. When properly

aligned, there should be no pulsing sounds or noise

coming from the belt.

!

Содержание 4224

Страница 17: ...17 ELECTRICAL SCHEMATIC 4224 Lathe ...

Страница 20: ...20 Stand Bed Assembly 4224 Lathe ...

Страница 23: ...23 Headstock Assembly 4224 Lathe ...

Страница 25: ...25 65 Bed Extension Assembly Optional 4224 Lathe ...

Страница 28: ...28 WMH Tool Group 2420 Vantage Drive Elgin Illinois 60123 Phone 800 274 6848 www wmhtoolgroup com ...