3

Replacement

1. Remove the FS nuts and bolts and then FS set from air

end.

2. Remove LP and HP tip seals from Fixed Scroll set and

Orbit scroll set. Using the tip of a ball-point pen at the

start will make it much easier to remove (See Figure 4).

3. Remove all dust from the Scroll wraps and tip seal groove

with clean cloth or compressed air before inserting the

new tip seals.

Maintenance (continued)

NOTE:

Replace tip seal on SLAE03EB and SLAE05EHP at 5,000

hours when operated at 145 psig.

The tip seal on the scroll compressor is self-lubricated

and allows the unit to operate effi ciently without oil and

expensive fi ltration. The tip seal should be replaced every

10,000 hours of operating @ 115 psig.

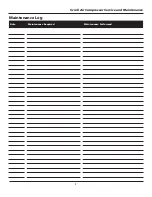

Confi rmation of the Parts

1. Confi rm if the tip seal set you purchased is correct for the

air end you are repairing. See part number 12 on Page 7

for tip seal set and corresponding pump model number.

One tip seal set contains all of the items in Figure 3

below.

2. Confi rm if the following parts are included (See Figure 3).

1

2

5

6

4

3

Figure 3

Tip Seal Removal

Figure 4

Item

No. Description

Qty.

1

HP tip seal for FS

1

2

LP tip seal for FS

1

3

HP tip seal for OS

1

4

LP tip seal for OS

1

5 Dust

Seal

1

6 Backup

Tube

1

HP= High Pressure

LP= Low Pressure

FS= Fixed Scroll

OS- Orbital Scroll

NOTE:

In order to distinguish between the tip seal for Fixed

Scroll and the tip seal for Orbit Scroll place the tip seal as

shown below then view from the arrow direction and refer

to the fi gure below.

Lip

(Inside)

Lip

(Bottom Side)

Facing

Left

Facing

Right

Fixed Scroll

Orbit Scroll

Scroll Air Compressor Service and Maintenance