17

To switch back on, turn the operating mode selection

switch to the central ‘OFF’ position.

Press the reset switch.

Release the rectangular safety lock (by pulling it back towards the handle),

then turn the round knob to the left to cause the cutting mechanism to

work in reverse for a few seconds and release any thick branches that

may have caused the blockage. Stop the machine then remove these

obstructions carefully from the feed hopper and discard them if too big.

Switch the device back on as described above.

Use the feeder to help feed material down the funnel as necessary.

After switching off automatically as a result of overload, the equipment

may not restart automatically if material remains trapped in the cutting

mechanism.

1

2

7

Restarting and using the blade reversing mechanism

Содержание 577147

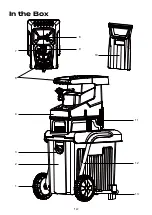

Страница 12: ...12 In the Box 11 8 9 4 6 7 10 3 1 2 12 13 ...