12

2.

Never exceed maximum and minimum pressure. Too low or too high pressure would cause noise

wear and tear or misfiring.

3.

When connecting air supply always keep hands and body away from discharge area of tool.

4.

A filter- regulator-lubrication is required and should be located as close to tool as possible.

5.

Keep air filter clean. A dirty filter will reduce the air pressure to the tool causing a reduction in power

and efficiency.

6.

For better performance, install a quick connector in your tool and quick coupler on the hose if

possible.

7.

Be sure all connections in air supply system are sealed to prevent air loss.

If you plan on installing a filter/ lubricator/regulator unit in your compressed air system, always follow

the connection instructions that come with the unit.

Typical filter/ lubricator/regulator installation order.

WARNING:

Exceeding the maximum permissible operating pressure may cause the nailer to

explode, blowing metal fragments in all directions. To protect yourself from serious personal

injury, DO NOT allow your air compressor to exceed the recommended pressure when

connected to this nailer!

MAINTENANCE

WARNING

: Disconnect the tool from the air compressor before adjusting, clearing jams,

servicing, Relocating and during non-operation.

1.

Regular lubrication of the tool is required. Add 2 to 6 drops of lubricant oil into the air inlet before

each work day or after 2 hours of continuous use depending on the characteristic of work piece or

type of fasteners.

2.

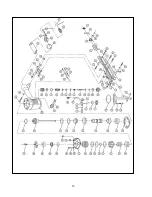

Check and change all worn or damaged o-rings, seals, etc. Tighten all the screws and caps to avoid

personal injury.

3.

Inspect trigger and safety mechanism to assure system is complete and functional with no loose or

missing parts.

4.

Keep magazine and workpiece contact trip clean and free of any dirt lint or abrasive particles.