Powered by Safety

®

25

Installation

01.4IB.51000C

Table C Bolt Torque Values

Bolt

Dimensions

(inches)

Bolt

Head

Torque

Ft-Lbs

Kg-M

5/8

55-70

7.6-9.7

1/2

35-50

4.8-6.9

3/8

20-30

2.8-4.2

1/4

5-7

0.7-0.97

Note

: The bolt head drawings in Table C

are not to scale. Locate the Bolting

Torque label on the equipment for an

accurate drawing of bolt sizes.

k. m

AIn

B

uS

A

SSemBly

AnD

I

nSulAtIon

To insulate the main bus assembly, remove the

rear compartment covers. Then bolt the splice

plate and bus bars together, following the

assembly instructions in

!

CAUTION

The operating temperature of conductors

in the switchgear may reach 105

°

C. Any

insulating material used in this switchgear

must be suitable for this temperature.

To provide adequate bus joint insulation, use

any of the following methods:

• Wrapping bus joints, using tape or heat

shrink material

• Applying bus insulating boots

1) Main Bus Joint Insulation

Main bus joints are insulated with either a

custom fitted boot or with hand applied

insulating tape.

will describe the

procedure for hand applied insulating

tape wrapped joints. After installing

main bus conductors the joints must be

insulated as follows.

a. Tighten the bus bar splice plate bolts

properly. See

Table C Bolt Torque Values.

Once the joints are insulated, it will

not be possible to retorque the bolts

without removing the boot.

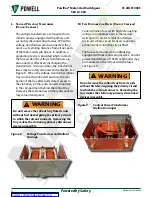

b. Place the boot over the joint (Figure 16).

Figure 16 Placing the Boot over the Joint

c. Align holes of each side of the boot.

d. Thread tie wraps through the holes and

pull tight, creating a seal (Figure 17, a).

e. An alternative method of assembly

uses push rivets (Figure 17, b). Push the

rivets completely through on both sides

of the boot. Verify the edges of the

boot seal.