12

OPERATION

TO OPERATE ON HILLS

CAUTION: Do not drive up or down hills

with slopes greater than 15° and do not

drive across any slope.

•

Choose the slowest speed before starting up or down

hills.

•

Avoid stopping or changing speed on hills.

•

If slowing is necessary, move throttle control lever to

slower position.

•

If stopping is absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

•

Move motion control lever to neutral (N) position.

IMPORTANT:

THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

•

To restart movement, slowly release parking brake and

clutch/brake pedal.

•

Slowly move motion control lever to slowest setting.

•

Make all turns slowly.

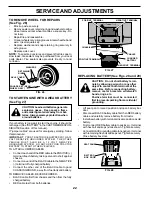

ATTACHMENT

CLUTCH LEVER

"DISENGAGED"

POSITION

ATTACHMENT

LIFT LEVER

HIGH POSI-

TION

"ENGAGED" POSITION

LOW

POSITION

FIG. 8

TOWING CARTS AND OTHER ATTACHMENTS

Tow only the attachments that are recommended by and

comply with specifications of the manufacturer of your

tractor. Use common sense when towing. Too heavy of a

load, while on a slope, is dangerous. Tires can lose traction

with the ground and cause you to lose control of your tractor.

FIG. 6

TO TRANSPORT (See Figs. 4 and 8)

When pushing or towing your tractor, be sure to disengage

transmission by placing freewheel control in freewheeling

position. Free wheel control is located at the rear drawbar of

tractor.

•

Raise attachment lift to highest position with attach-

ment lift control.

•

Pull freewheel control out and down into the slot and

release so it is held in the disengaged position.

•

Do not push or tow tractor at more than two (2) MPH.

•

To reengage transmission, reverse above procedure.

NOTE: To protect hood from damage when transporting

your tractor on a truck or a trailer, be sure hood is closed and

secured to tractor. Use an appropriate means of tying hood

to tractor (rope, cord, etc.).

DEFLECTOR

SHIELD

TO OPERATE MOWER (See Fig. 7)

Your tractor is equipped with an operator presence sensing

switch. Any attempt by the operator to leave the seat with

the engine running and the attachment clutch engaged will

shut off the engine.

•

Select desired height of cut.

•

Start mower blades by engaging attachment clutch

control.

•

TO STOP MOWER BLADES - disengage attachment

clutch control.

CAUTION: Do not operate the mower

without either the entire grass catcher,

on mowers so equipped, or the deflector

shield in place.

FIG. 7

TO ADJUST GAUGE WHEELS (See Fig. 6)

Gauge wheels are properly adjusted when they are slightly

off the ground when mower is at the desired cutting height in

operating position. Gauge wheels then keep the deck in

proper position to help prevent scalping in most terrain

conditions.

•

Adjust gauge wheels with tractor on a flat level surface.

•

Adjust mower to desired cutting height (See “TO AD-

JUST MOWER CUTTING HEIGHT” in the Operation

section of this manual).

•

With mower in desired height of cut position, gauge

wheels should be assembled so they are slightly off the

ground. Install gauge wheel in appropriate hole with

shoulder bolt, 17/32 washer, 3/8 washer, and 3/8-16

locknut and tighten securely.

•

Repeat for opposite side installing gauge wheel in same

adjustment hole.

GAUGE WHEEL

GAUGE

WHEEL

MOUNT-

ING

BRACKET

3/8-16

LOCKNUT

3/8 WASHER

SHOULDER

BOLT

17/32 WASHER