4.13

FUEL INJECTION

4

FUEL INJECTORS

Operation Overview

NOTE: All EFI units utilize quick connect fuel lines.

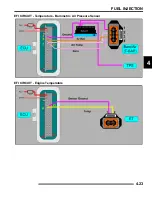

The fuel injectors mount into the intake manifold, and the fuel

rail attaches to them at the top end. Replaceable O-Rings on both

ends of the injector prevent external fuel leaks and also insulate

it from heat and vibration.

When the key switch is on, the fuel rail is pressurized, and

voltage is present at the injector. At the proper instant, the ECU

completes the ground circuit, energizing the injector. The valve

needle in the injector is opened electromagnetically, and the

pressure in the fuel rail forces fuel down through the inside. The

“director plate” at the tip of the injector (see inset) contains a

series of calibrated openings which directs the fuel into the

intake port in a cone-shaped spray pattern.

The injector is opened and closed once for each crankshaft

revolution, however only one-half the total amount of fuel

needed for one firing is injected during each opening. The

amount of fuel injected is controlled by the ECU and determined

by the length of time the valve needle is held open, also referred

to as the “injection duration” or “pulse width”. It may vary in

length from 1.5-8 milliseconds depending on the speed and load

requirements of the engine.

Fuel Injector Service

Injector problems typically fall into three general categories-

electrical, dirty/clogged, or leakage. An electrical problem

usually causes one or both of the injectors to stop functioning.

Several methods may be used to check if the injectors are

operating.

• With the engine running at idle, feel for operational

vibration, indicating that they are opening and closing.

• When temperatures prohibit touching, listen for a

buzzing or clicking sound with a screwdriver or

mechanic's stethoscope.

• Disconnect the electrical connector from an injector and

listen for a change in idle performance (only running on

one cylinder) or a change in injector noise or vibration.

NOTE: Do not apply voltage directly to the fuel

injector(s). Excessive voltage will burn out the

injector(s). Do not ground the injector(s) with the

ignition "on". lnjector(s) will open/turn on if relay is

energized.

If an injector is not operating, it can indicate either a bad injector,

or a wiring/electrical connection problem. Check as follows:

Injector leakage is very unlikely, but in rare instances it can be

internal (past the tip of the valve needle), or external (weeping

around the injector body). The loss of system pressure from the

leakage can cause hot restart problems and longer cranking

times.

Injector problems due to dirt or clogging are unlikely due to the

design of the injectors, the high fuel pressure, the use of filters

and the detergent additives in the gasoline. Symptoms that could

be caused by dirty/clogged injectors include rough idle,

hesitation/stumble during acceleration, or triggering of fault

codes related to fuel delivery. Injector clogging is usually caused

by a buildup of deposits on the director plate, restricting the flow

of fuel, resulting in a poor spray pattern. Some contributing

factors to injector clogging include; dirty air filters, higher than

normal operating temperatures, short operating intervals and

dirty, incorrect, or poor quality fuel. Cleaning of clogged

injectors is not recommended; they should be replaced.

Additives and higher grades of fuel can be used as a preventative

measure if clogging has been a problem.

Fuel Injector Replacement

1.

Engine must be cool. Depressurize fuel system through

test valve in fuel rail.

2.

Remove the front fender assembly and fuel tank.

3.

Thoroughly clean the area around and including the throttle

body/manifold and the injectors.

4.

Disconnect the fuel injector harness(s) at the ECU.

5.

Remove the fuel rail mounting screw and carefully loosen

/ pull the rail away from the injectors.

6.

Reverse the procedures to install the new injector(s) and

reassemble. Use new O-rings any time an injector is

removed (new replacement injectors include new O-rings).

Lubricate O-rings lightly with oil to aid installation. Torque

the fuel rail mounting screw to specification.

Injector

=

T

Fuel Rail Mount Screws

16-20 ft. lbs. (22.6-27 Nm)

Содержание Sportsman 800 EFI

Страница 4: ...NOTES ...

Страница 18: ...NOTES GENERAL INFORMATION 1 14 ...

Страница 25: ...2 7 MAINTENANCE 2 LUBRICATION FLUIDS SPORTSMAN Component Locations Sportsman Only Deluxe ...

Страница 55: ...2 37 MAINTENANCE 2 Maintenance Schedule Service Date Hours Miles Service Performed Serviced By ...

Страница 56: ...2 38 MAINTENANCE Maintenance Schedule Service Date Hours Miles Service Performed Serviced By ...

Страница 116: ...NOTES ENGINE 3 60 ...

Страница 137: ...4 21 FUEL INJECTION 4 EFI CIRCUIT Power On EFI CIRCUIT Crank Position Sensor ...

Страница 138: ...4 22 FUEL INJECTION EFI CIRCUIT Fuel Pump EFI CIRCUIT Throttle Position Sensor ...

Страница 139: ...4 23 FUEL INJECTION 4 EFI CIRCUIT Temperature Barometric Air Pressure Sensor EFI CIRCUIT Engine Temperature ...

Страница 140: ...4 24 FUEL INJECTION EFI CIRCUIT Malfunction Indicator Light ...

Страница 167: ...5 27 BODY STEERING SUSPENSION 5 X2 CARGO BOX Exploded View ...

Страница 170: ...5 30 BODY STEERING SUSPENSION X2 SEAT ASSEMBLY Exploded Views ...

Страница 174: ...NOTES BODY STEERING SUSPENSION 5 34 ...

Страница 206: ...NOTES CLUTCH SYSTEM 6 32 ...

Страница 244: ...7 38 FINAL DRIVE Rear Gearcase Exploded View ...

Страница 245: ...TRANSMISSION 8 1 CHAPTER 8 TRANSMISSION 8 SPORTSMAN 8 3 8 18 SPORTSMAN X2 8 19 8 38 ...

Страница 246: ...NOTES TRANSMISSION 8 2 ...

Страница 248: ...8 4 SPORTSMAN TRANSMISSION TRANSMISSION EXPLODED VIEW Sportsman Transmission ...

Страница 265: ...8 21 X2 Touring Transmission 8 242 262 262 262 262 262 ...

Страница 266: ...8 22 X2 Touring Transmission Mounting Exploded View x2 x3 x4 x4 x2 x1 x1 x1 ...

Страница 312: ...NOTES BRAKES 9 30 ...

Страница 322: ...10 10 ELECTRICAL SPEEDOMETER TROUBLESHOOTING Test 1 No All Wheel Drive ...

Страница 323: ...10 11 ELECTRICAL 10 TEST 2 No Display TEST 3 No Reverse Speed Limit ...

Страница 324: ...10 12 ELECTRICAL TEST 4 No AWD Hub Safety Limiter ...

Страница 325: ...10 13 ELECTRICAL 10 TEST 5 Reverse Speed Limiter TEST 6 Speed Sensor ...

Страница 326: ...10 14 ELECTRICAL TEST 7 No Fuel Gauge TEST 8 Transmission Switch ...

Страница 357: ...10 45 ELECTRICAL 10 BASIC WINCH WIRING PRE WIRED MODELS ...

Страница 367: ...10 55 ELECTRICAL 10 Cooling Fan EFI Fuel Pump EFI ...

Страница 368: ...10 56 ELECTRICAL Gear Switch EFI Power Circuit EFI ...

Страница 369: ...10 57 ELECTRICAL 10 Reverse Override EFI Fan Control EFI ...

Страница 370: ...10 58 ELECTRICAL Start Circuit EFI Start Enable EFI ...

Страница 373: ...11 3 800 TOURING EFI INTERNATIONAL 11 Exploded View Foot Brake Supply Hand Brake Supply ...

Страница 375: ...11 5 800 TOURING EFI INTERNATIONAL 11 800 TOURING EFI INTERNATIONAL ELECTRICAL Turn Hazard Signal Diagram ...

Страница 376: ...NOTES 800 TOURING EFI INTERNATIONAL 11 6 ...

Страница 382: ...IX 6 Intentional Blank Page ...

Страница 383: ...WD 1 WIRE DIAGRAM 2008 SPORTSMAN 800 EFI WIRE DIAGRAM ...

Страница 384: ...WD 2 WIRE DIAGRAM ...

Страница 385: ...WD 3 WIRE DIAGRAM 2008 SPORTSMAN 700 X2 800 TOURING EFI WIRE DIAGRAM ...

Страница 386: ...WD 4 WIRE DIAGRAM ...

Страница 387: ...WD 5 WIRE DIAGRAM 2008 SPORTSMAN 800 TOURING EFI INTERNATIONAL WIRE DIAGRAM ...

Страница 388: ...WD 6 WIRE DIAGRAM ...