NG 2D1D411A-F31+

AP G1A-111P

NG 2D1D411A-F31+

AP G1A-111P

NG 2D1D411A-F31+

AP G1A-111P

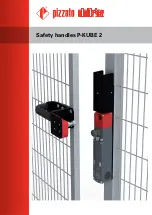

Safety handles P-KUBE 2

1

Safety handles

P-KUBE 2

This integrated closing device can be applied on guards or protections of perimetric safety barriers, where it is required control on access to

dangerous areas of a machinery or plant.

Application field

One of the most relevant features of the NG line combined with P-KUBE 2 handle is the optional connection

in series of several switches, up to a maximum number of 32 devices, while maintaining the maximum PLe

safety level prescribed by

the EN 13849-1 standard and the SIL3 safety level according to

the EN 62061 standard. Such connection method is permitted

in safety systems where a safety module, which evaluates the

outputs of the last NG switch, is present at the end of the chain.

The fact that the PLe safety level can be maintained, even with

32 switches connected in series, is indicative of the extremely

safe structure found inside each individual device.

Maximum safety with a single device

Constructed with redundant electronic technology, the NG series switches combined with P-KUBE 2 handle,

make it possible to create circuits having maximum PLe and SIL3 safety levels by fitting just one device on

the protection. This avoids expensive wiring on the field and allows quicker installation. Inside the panel, the two electronic safety outputs must

be connected to a Pizzato Elettrica safety module or to a safety PLC.

Pizzato Elettrica

safety module

CS series

Connection of several switches in series

The new P-KUBE 2 safety handle, mounted in combination with the NG series RFID safety switch with block, creates an integrated protection

closing system with relating control of access to dangerous areas; such new combination makes it possible to obtain, with one single device,

an access control function complying with category 4, PLe according to EN 13849-1 or SIL3 according to EN 62061.

Presentation

NG series features an electronic system based on RFID technology to

detect the actuator. This system gives a different coding to each actua-

tor and makes it impossible to tamper with a device by

using another actuator belonging to the same series.

The actuators may have millions of different coding

combinations, and are therefore classified as actua-

tors with a high coding level, according to ISO 14119.

RFID actuators with high coding level

Anti-panic release button

The release button, facing the inside of the

machine, allows an operator which may have

been involuntarily trapped to get out, even

in case of power cuts and in any operating

condition. To reset the switch, just return the

button to its initial position.

The anti-panic button can be freely length-

ened by means of appropriate extensions,

so that it can also be mounted on very thick

uprights (see accessories).

5 LEDs for immediate diagnosis

As the LEDs have been designed for

quick immediate diagnosis, the status of

each input and output is highlighted by

one specific LED. This makes it possible

to quickly identify the interruption

points in the safe chain, which device

is released, which door is opened and

any errors inside the device. All that in a

straightforward way without needing to

decode complex blinking sequences.

Centring

The switch is provided with a wide

centring inlet for the actuator pin.

Such solution makes it easier to

align the actuator with the hole

found in the head during the fitting

stage. Moreover, this solution

drastically reduces any probable

collisions between the actuator

and the switch, also allowing it to

be fitted on inaccurate doors.

Dustproof

The switch is provided with a through hole

for inserting the actuator and, thanks to this

peculiarity, any dust which may go inside the

actuator hole can always come out of the opposite

side instead of being left there. Moreover, the lock

pin is provided with an external diaphragm gasket

which makes it suitable for any environment

where dust is present.

The NG series switches by Pizzato Elettrica,

besides having an IP67 protection degree,

have passed the test proving their IP69K

protection degree according to the

prescriptions established by the ISO 20653

standard. Therefore they are suitable for use in

machineries subjected to intense washing with high pressure and high

temperature water jets and for any condition or environment where a

particular attention for cleanness and hygiene is required, such as in

food or pharmaceutical industry.

High protection degree

Содержание P-KUBE 2

Страница 1: ...Safety handles P KUBE 2...