8

Operation

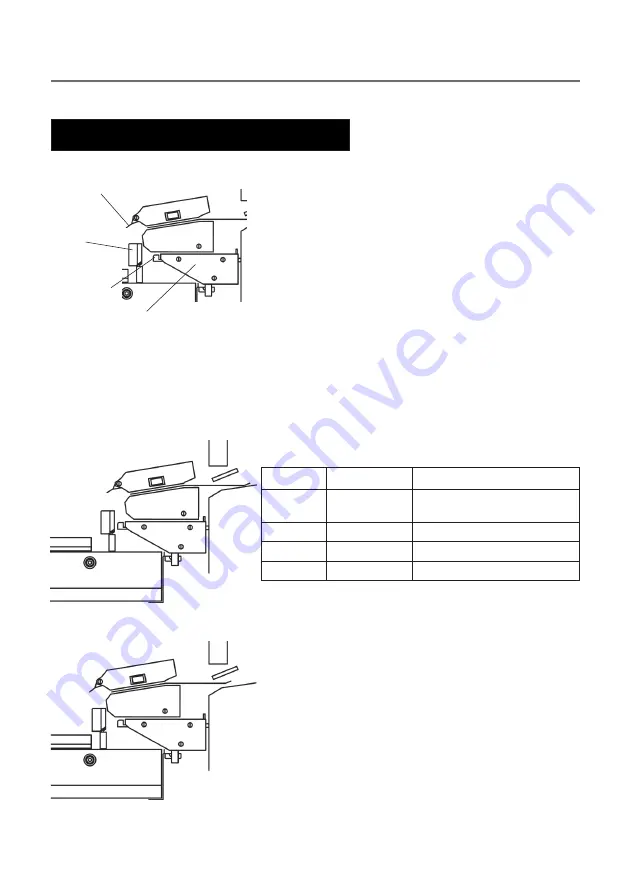

paper

deflector

paper

guide

adjustment

lever

output module

bracket

output module locked in the

innermost position

output module in the outermost

position (adjustment lever in pos. 1)

The purpose of the output module is to ensure that

the set from the collator is fed correctly to the inserter

document table. To achieve this, the position of the

output module is adjustable to match different paper

sizes and how the set is orientated.

On the output module bracket there is an adjustment

lever and a scale. The adjustment lever can be

placed in five different positions, where a higher

number places the output module closer to the

collator. To change position of the adjustment lever,

first push the output module towards the collator

until it locks in the innermost position.

The recommendations in the table below are

guidelines. The adjustments can vary depending on

paper quality, paper weight etc.

Paper size Feed direction Adjustment lever position

A4

Portrait

Output module in innermost

position.

A4

Landscape

3

8.5" x 11"

Portrait

5

8.5" x 11"

Landscape

3

Note: Before moving the adjustment lever, push

the output module towards the collator

until it locks and the adjustment lever

moves freely.

The leading edge of the set should land between

the feeding belts on the inserter document table.

When necessary, adjust the paper deflector.

Change the position of the adjustment lever if:

• The set bounces back, up on the inserter

document table side guide - move the adjustment

lever to a higher number.

• The set stays on the paper guide - move the

adjustment lever to a lower number.

4.3 Adjusting the output module

Содержание DI875

Страница 1: ...Operating Guide F612 F615 Collator ...

Страница 16: ...15 Notes ...

Страница 17: ...16 Notes ...