____________________________________________________________________________________________________________

PFT G 5 c FU 230

3

PFT Sales Information

01.2005

____________________________________________________________________________________________________________

________________________________________________________________________________________

Knauf PFT GmbH & Co. KG

Telephone

09323 / 31-760

PO Box 60

Telefax

09323 / 31-770

D-97343 Iphofen

Internet

www.pft.de

________________________________________________________________________________________

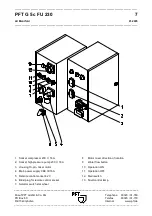

Initial inspection after delivery

An indispensable task of all technicians delivering the PFT G 5 c FU 230 mixing pump

is the inspection of the machine settings at the end of the first spraying phase. The

factory settings can be changed during the first operation. If these changes are not

corrected in time, immediately after initial start-up, then operating trouble can be

expected.

After putting the PFT G 5 c FU 230 mixing pump into service and giving appropriate

instructions, after about two hours, the technician must always carry out the following

checks / make the following settings:

1.

Water safety switch

2.

Pump pressure, backpressure

3.

Pressure relief valve on compressor

4.

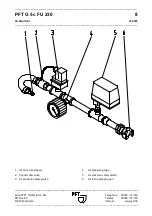

Air nozzle tube clearance (spray pattern)

5.

Air safety switch

6.

Compressor safety switch

7.

Remote control switch

8.

Pressure reducer

9.

Motor protection switch