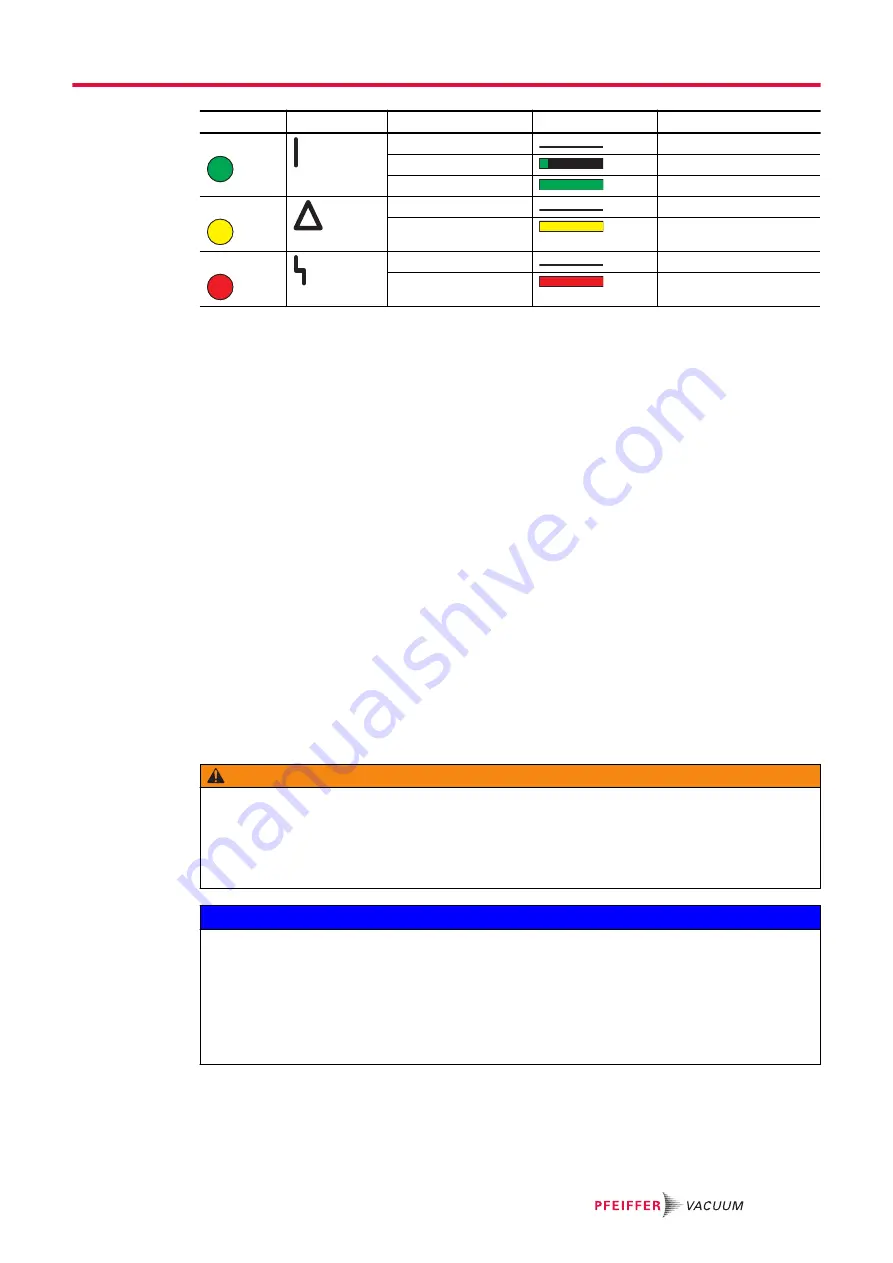

LED

Symbol

LED status

Display

Meaning

Green

Off

without current

On, flashing

"Pump OFF"

On, constant

"Pump ON"

Yellow

Off

no warning

On, constant

Warning

Red

Off

No errors

On, constant

Error

Tbl. 17:

Meaning of the LEDs

8.5.2 Temperature monitoring

Depending on the sensor type, temperature thresholds for warning and malfunction messages are stor-

ed immutably in the parameter set of the electronic drive unit. If a measured value exceeds the thresh-

old, the vacuum pump is switched to a safe state.

With an oil temperature (T > 85 °C), only a "

Warning

" is issued.

With impermissibly high temperature (T > 95 °C), the vacuum pump is switched off with an "

Error

". Af-

ter cooling down, the vacuum pump does

not

start automatically.

Acknowledge error - Query status

► Set parameter

[P:010]

to "0/1".

8.5.3 Check the lubricant level

Check the lubricant level

1. Regularly check the lubricant level while the vacuum pump is running and at operating tempera-

ture.

2. Make sure that the level is in the area at the center of the sight glass.

3. Check operating fluid fill level daily during continuous operation, and every time vacuum pump is

switched on.

8.6 Switching off and venting

WARNING

Risk of crushing on rotating parts when reaching into the open flange

The pistons continue to run in the vacuum after switching off the motor, and can trap fingers and

hands within their reach.

► Wait until the vacuum pump comes to a complete standstill.

► Secure the vacuum pump against re-start.

NOTICE

Risk of damage from gas backflow into the roots pump

Due to the backflow of process gas, the electronic equipment is susceptible to irreversible damage

caused by regenerative energy produced with rotation of the piston.

► Equip the vacuum pump with a facility that prevents the backflow of gases.

► Use, e.g. a shut-off facility on the fore-vacuum side and block the line directly after switching off

the vacuum pump.

► As an alternative, use a backing pump with integrated vacuum safety valve.

The "Pumping station" parameter

[P:010]

comprises operation of the vacuum pump with control of all

connected interfaces and configurations.

Operation

45/68