© 2009

4

24” ADA-Compliant Series Operation / Installation Manual

CAUTION

To prevent damage to the countertop and unit underneath, do not

place heavy objects on countertop directly above the unit.

6. Check interior door openings inside unit and ensure unit is level.

SHELVING

IMPORTANT: To achieve maximum performance, interior louver open-

ings and fan guard openings should never be obstructed.

Refrigerator

The single door unit comes standard with two black vinyl coated

adjustable full extension pullout shelves.

Wine Reserve

The single door unit comes standard with five full extension black vinyl

coated wine racks capable of storing 40 total wine bottles and addi-

tional storage on the bottom for 8 more bottles. Shelves are removable

and adjustable to accommodate oversized (magnum) bottles.

INSTALLATION

CAUTION

Finished flooring should be protected with appropriate material

to avoid damage from moving the unit.

If unit has been laid on its back or sides, place unit upright and

allow minimum of 24 hours before connecting power.

1. Plug the unit into the 15 amp grounded outlet located in the instal-

lation opening. With power applied to the unit, check that lighting

and cooling function operate properly, then turn off power to the

wall outlet at the circuit breaker.

WARNING

Shut off power to the wall outlet before installing unit into the

opening.

2. Check that the following are level and square:

- front face and interior opening

- installation opening and floor surface

- countertop bottom front edge

IMPORTANT: The floor under the unit must be at the same level as the

surrounding finished floor.

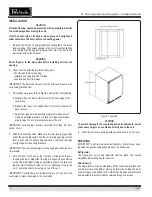

3. If all surfaces are level, refer to Figure 3 and perform the following:

a. Measure from the floor to the bottom of the front edge of the

countertop.

b. Measure the rear of unit cabinet from floor to top of cabinet, at

back corners.

c. Adjust rear legs so B measurement equals A measurement.

Using an adjustable wrench or pliers, turn legs counterclock-

wise to raise the unit or clockwise to lower the unit.

IMPORTANT: Levelling legs should not extend more than 3/4” from

bottom of unit.

4. Slide the unit into position. Make sure the rear leveling legs slide

under the anit-tip brackets. Push the unit into the opening until the

door is flush with the surrounding cabinetry, or until the rear legs

are tight against the anti-tip brackets.

IMPORTANT: The rear leveling legs must be engaged under the anti-

tip brackets.

5. Shim the front of the unit so the front door is flush with the sur-

rounding cabinetry. Adjust the front legs to support the countertop

at the shimmed height. Using an adjustable wrench or pliers, turn

legs counterclockwise to raise the unit or clockwise to lower the

unit. Countertop should be resting on top of the unit.

IMPORTANT: If countertop is not resting entirely on unit top, shim the

countertop to prevent damage to the countertop.

Figure 3. Leveling

Содержание HA24BB1L

Страница 10: ...2008 10 24 ADA Compliant Series Operation Installation Manual Figure 8 Solid Wood Overlay Door Panel...

Страница 12: ...2008 12 24 ADA Compliant Series Operation Installation Manual Figure 9 Solid Wood Overlay Drawers...

Страница 19: ...2008 19 24 ADA Compliant Series Operation Installation Manual...