TPD 1399E

Chapter 5

Page 15

Engine Cooling Systems

Sea Water Systems

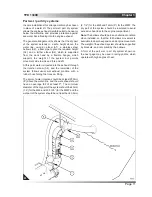

A completely separate sea water system should be

provided for each engine to prevent a blockage

resulting in the need to shut down more than one

engine. A typical system is shown on (A).

The water intake fitting (A1) should not project

appreciably below the bottom of the hull and it should

be situated well clear of other components such as

shafts, logs, rudders to prevent flow problems at high

speeds. If desired the rear edge of the water intake

may be allowed to project more than the front, by no

more than 6mm, to give a slight scoop effect, but if

this is done it is necessary to locate the fitting so that

it cannot be inadvertently partially rotated.

The intake fittings and pipework should have a

minimum bore of 25mm. Inboard of the intake fitting

a sea cock must be provided (A2). This should be of

the full flow type giving unobstructed passage to the

water in the open position, with a minimum bore of

25mm.

Between the intake fitting and the sea water pump

on the engine, there should be a strainer (A3) which

should be easily accessible for routine examination,

and the lid should be easily removable. Where

possible mount the strainer so that the top is just

above the waterline - this will allow the strainer to be

cleaned without closing the sea cock.

From the sea water strainer a pipe should be run to

the sea water pump inlet connection on the engine (

B1). The pipe may either be mainly rigid, of for example

copper or cupro-nickel, or flexible, but only flexible

hose which is reinforced to prevent collapse should

be used. Rubber hose connections in the sea water

system should be kept as short as possible and should

be reinforced with a minimum of three layers of

canvas. The system must be sufficiently flexible to

permit the engine to move on its anti-vibration

mountings. The sea water pump connection is for

hose with a 32mm bore.

A small supply of seawater is often needed to cool

and lubricate the shaft log. A connection point (B2) is

provided to suit 10mm bore hose.

Care should be taken to use compatible materials

in the sea water systems, to prevent excessive

electrolytic corrosion. Systems incorporating copper,

cupro-nickel, stainless steel Type 316, gun-metal,

silver solder, and aluminium brass will generally be

satisfactory. Components made from lead, iron, steel,

aluminium or its alloys, zinc or magnesium, should be

generally avoided.

Содержание M65

Страница 1: ... Installation Manual GB Part No TPD 1399E M65 M85T ...

Страница 2: ......

Страница 4: ...TPD1399E ...

Страница 20: ...Chapter 4 TPD 1399E Page 14 ...

Страница 26: ...Chapter 6 TPD 1399E Page 20 ...

Страница 28: ...Chapter 7 TPD 1399E Page 22 ...

Страница 33: ...TPD 1399E Chapter 7 Page 27 ...

Страница 34: ...Chapter 7 TPD 1399E Page 28 ...

Страница 38: ...Chapter 7 TPD 1399E Page 32 ...

Страница 40: ...Chapter 8 TPD 1399E Page 34 ...

Страница 44: ...Chapter 9 TPD 1399E Page 38 ...

Страница 46: ...Chapter 10 TPD 1399E Page 38 ...

Страница 52: ...Chapter 11 TPD 1399E Page 44 ...