Engine Starting

i02109067

Before

Starting

Engine

Perform

the

required

daily

maintenance

and

other

periodic

maintenance

before

the

engine

is

started.

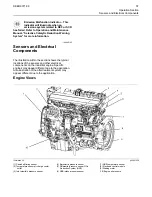

Inspect

the

engine

compartment.

This

inspection

can

help

prevent

major

repairs

at

a

later

date.

Refer

to

the

Operation

and

Maintenance

Manual,

“Maintenance

Interval

Schedule”

for

more

information.

• For the maximum service life of the engine, make

a thorough inspection before the engine is started.

Look for the following items: oil leaks, coolant

leaks, loose bolts and trash buildup. Remove trash

buildup and arrange for repairs, as needed.

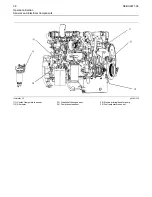

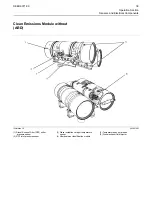

• Inspect the aftercooler for loose connections and

for debris buildup.

• Inspect the cooling system hoses for cracks and

for loose clamps.

• Inspect the alternator and accessory drive belts for

cracks, breaks, and other damage.

• Inspect the wiring for loose connections and for

worn wires or frayed wires.

• Check the fuel supply. Drain water from the water

separator (if equipped). Open the fuel supply

valve.

NOTICE

All valves in the fuel return line must be open before

and during engine operation to help prevent high fuel

pressure. High fuel pressure may cause filter housing

failure or other damage.

If the engine has not been started for several weeks,

fuel may have drained from the fuel system. Air may

have entered the filter housing. Also, when fuel filters

have been changed, some air pockets will be trapped

in the engine. In these instances, prime the fuel

system. Refer to the Operation and Maintenance

Manual, “Fuel System - Prime” for more information

on priming the fuel system.

Engine exhaust contains products of combustion

which may be harmful to your health. Always

start and operate the engine in a well ventilated

area and, if in an enclosed area, vent the exhaust

to the outside.

• Do not start the engine or move any of the controls

if there is a

“

DO NOT OPERATE

”

warning tag or

similar warning tag attached to the start switch or

to the controls.

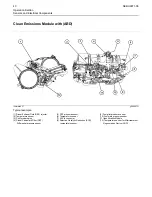

• Ensure that the areas around the rotating parts are

clear.

• All of the guards must be put in place. Check for

damaged guards or for missing guards. Repair

any damaged guards. Replace damaged guards

and/or missing guards.

• Disconnect any battery chargers that are not

protected against the high current drain that is

created when the electric starting motor (if

equipped) is engaged. Check electrical cables and

check the battery for poor connections and for

corrosion.

• Reset all of the shutoffs or alarm components.

• Check the engine lubrication oil level. Maintain the

oil level between the

“

ADD

”

mark and the

“

FULL

”

mark on the oil level gauge.

• Check the coolant level. Observe the coolant level

in the coolant recovery tank (if equipped). Maintain

the coolant level to the

“

FULL

”

mark on the coolant

recovery tank.

• If the engine is not equipped with a coolant

recovery tank maintain the coolant level within

13 mm (0.5 inch) of the bottom of the filler pipe. If

the engine is equipped with a sight glass, maintain

the coolant level in the sight glass.

• Observe the air cleaner service indicator (if

equipped). Service the air cleaner when the yellow

diaphragm enters the red zone, or when the red

piston locks in the visible position.

• Ensure that any driven equipment has been

disengaged. Minimize electrical loads or remove

any electrical loads.

i04132731

Cold

Weather

Starting

Startability

will

be

improved

at

temperatures

below

10°C

(50°F)

from

the

use

of

a

cylinder

block

coolant

heater

or

from

other

means

that

are

used

to

heat

the

crankcase

oil.

Some

engine

applications

use

a

jacket

water

heater

to

improve

startability.

Use

of

a

jacket

water

heater

will

help

reduce

white

smoke

and

misfire

during

start-up

in

cold

weather.

48

SEBU9071-06

Содержание 2206F-E13TA

Страница 126: ......

Страница 128: ...SEBU9071 2020 Perkins Engines Company Limited All Rights Reserved 128 December 2020 ...