Failure of the Coolant Temperature

Sensor

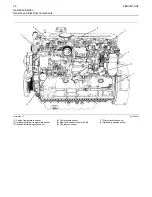

The ECM (5) will detect a failure of the coolant

temperature sensor. The diagnostic lamp will warn

the operator about the status of the coolant

temperature sensor. A failure of the coolant

temperature sensor will not cause a shutdown of the

engine or any horsepower change. In order to check

the correct operation of the sensor, refer to

Troubleshooting, “Engine Temperature Sensor Circuit

- Test”.

Intake Manifold Air Temperature

Sensor 2

The intake manifold air temperature sensor

measures the intake air temperature. A signal is sent

to the ECM (5). The intake manifold air temperature

sensor is also used by the ECM to determine

initiation of the Cold Start Strategy.

In order to check the correct operation of the sensor,

refer to Troubleshooting, “EngineTemperature

Sensor Circuit - Test”.

Intake Manifold Pressure Sensor 3

The intake manifold pressure sensor measures

pressure in the manifold. A signal is sent to the ECM

(5).

Fuel Pressure Sensor 4

The fuel pressure sensor measures the fuel pressure

in the fuel manifold. A signal is sent to the ECM (5).

Electronic Control Module 5

The ECM is the control computer of the engine. The

ECM provides power to the electronics. The ECM

monitors data that is input from the sensors of the

engine. The ECM acts as a governor in order to

control the speed and the power of the engine.

The ECM adjusts injection timing and fuel pressure

for the best engine performance, the best fuel

economy and the best control of exhaust emissions.

Engine Oil Pressure Sensor 6

The engine oil pressure sensor is an absolute

pressure sensor that measures the engine oil

pressure in the main oil gallery. The engine oil

pressure sensor detects engine oil pressure for

diagnostic purposes. The engine oil pressure sensor

sends a signal to the ECM (5).

Low Oil Pressure Warning

The setpoint for the low pressure warning is

dependent upon the engine speed. The fault will be

active and logged only if the engine has been running

for more than 8 seconds.

Very Low Oil Pressure Warning

The very low oil pressure setpoint is dependent upon

the engine speed. If the DERATE mode of the engine

monitoring system is selected, the ECM (5) will

derate the engine power. The engine horsepower will

be limited.

Failure of the Engine Oil Pressure Sensor

The ECM (5) will detect failure of the engine oil

pressure sensor. The diagnostic lamp warns the user

about the status of the engine oil pressure sensor.

The engine oil pressure related strategies will be

disabled in the event of a failure of the engine oil

pressure sensor. A failure of the engine oil pressure

sensor will not cause a shutdown of the engine or

any horsepower change. In order to check the correct

operation of the sensor, refer to Troubleshooting, “5

Volt Sensor Supply Circuit - Test”.

Primary Speed/Timing Sensor 7

If the ECM (5) does not receive a signal from the

primary speed/timing sensor , the

“

DIAGNOSTIC

”

lamp will indicate a diagnostic fault code which will be

logged in the ECM memory.

If the ECM does not receive a signal from the primary

speed/timing sensor (7), the ECM will read the signal

from the secondary speed/timing sensor (8). The

ECM continually checks in order to determine if there

is a signal from both sensors.

Intermittent failure of the sensors will cause erratic

engine control.

Failure of the Primary Speed/Timing

Sensor

Correct operation of the primary speed/timing sensor

is essential. Software in the ECM protects against

reverse running of the engine. If the primary speed/

timing sensor fails there is no automatic protection

against reverse running. In some applications, it is

possible for the transmission to run the engine in

reverse. In this event, Stop the engine immediately.

Turn the keyswitch to the

“

OFF

”

position.

SEBU8119-04

35