NOTICE

When any servicing or repair of the engine cooling

system is performed the procedure must be per-

formed with the engine on level ground. This will al-

low you to accurately check the coolant level. This

will also help in avoiding the risk of introducing an air

lock into the coolant system.

1.

Slowly loosen the cooling system filler cap in order

to relieve the pressure. Remove the cooling

system filler cap.

Note:

Always discard drained fluids according to

local regulations.

2.

If necessary, drain some coolant from the cooling

system into a suitable container in order to allow

space for the extra SCA.

3.

Add the correct amount of SCA. Refer to the

Operation and Maintenance Manual, “Refill

Capacities and Recommendations” for more

information on SCA requirements.

4.

Clean the cooling system filler cap and inspect the

gasket. If the gasket is damaged, discard the old

filler cap and install a new filler cap. If the gasket is

not damaged, use a suitable pressurizing pump in

order to pressure test the filler cap. The correct

pressure is stamped on the face of the filler cap. If

the filler cap does not retain the correct pressure,

install a new filler cap.

i02788266

Crankcase

Breather

(Canister)

-

Replace

NOTICE

Ensure that the engine is stopped before any servic-

ing or repair is performed.

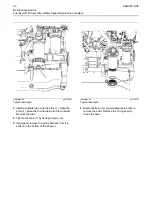

1.

Place a container under canister (2).

2.

Clean the outside of the canister. Use a suitable

tool in order to remove the canister.

Illustration 40

g01392831

Typical example

3.

Lubricate O ring seal (1) on the new canister with

clean engine lubricating oil.

4.

Install the new canister. Spin on the canister until

the O ring seal contacts the sealing surface (3).

Then rotate the canister ¾ of a full turn.

5.

Remove the container. Dispose of the old canister

and any split oil in a safe place.

i02151646

Driven

Equipment

-

Check

Refer

to

the

OEM

specifications

for

more

information

on

the

following

maintenance

recommendations

for

the

driven

equipment:

• Inspection

• Adjustment

• Lubrication

• Other maintenance recommendations

Perform any maintenance for the driven equipment

which is recommended by the OEM.

SEBU8119-04

77