7.2 Repair

CAUTION!

Personal protective equipment must be used before removing dirt and

contamination from the steel surface.

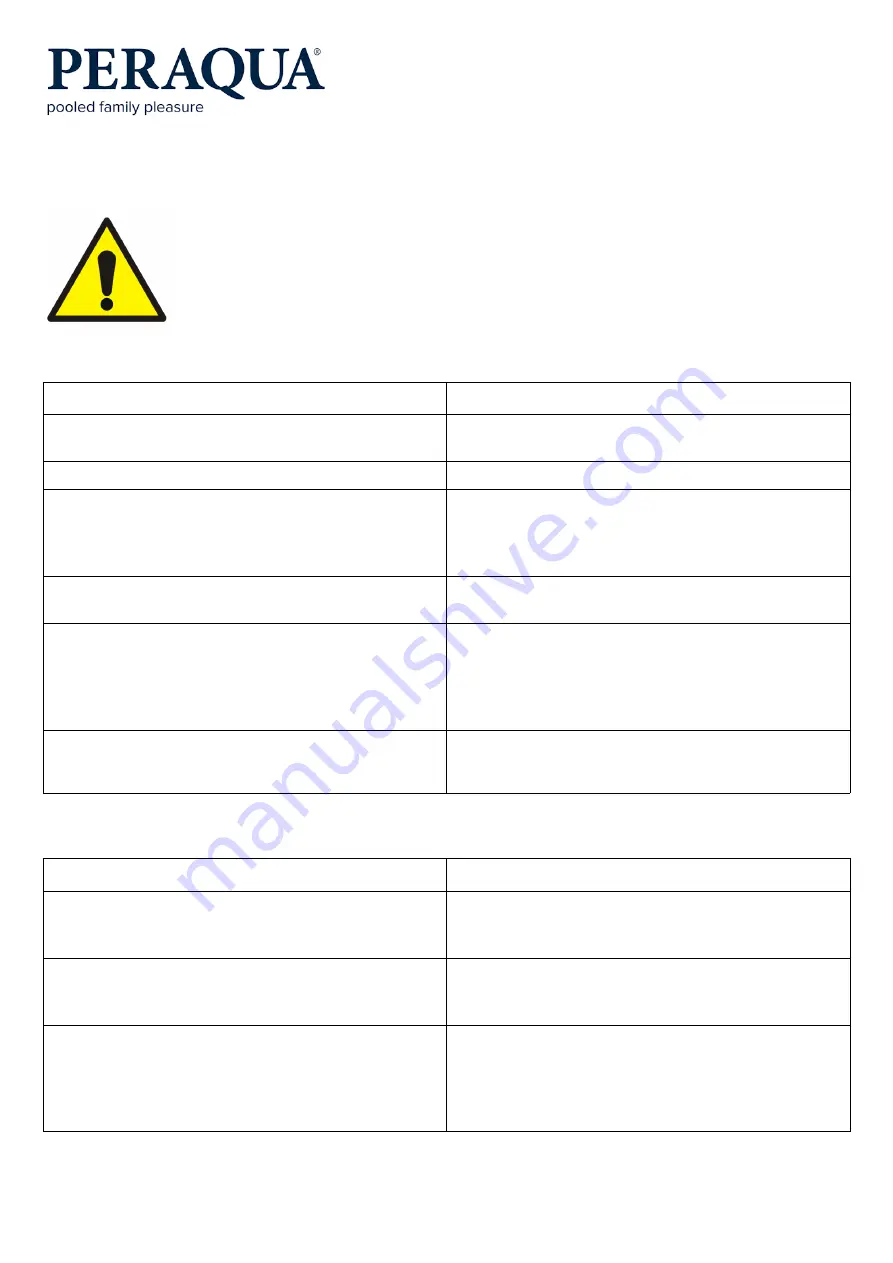

7.2.1 Cleaning of pollution

type of pollution

cleaning products

fingerprints

soapy water or detergent, chloride-free glass

cleaners

limescale

solution of ¼ vinegar and hot water

¾

oils and lubricants

alcohol-based products (including methyl

alcohol and isopropyl alcohol) solvents, e.g.

acetone, cleaning agents for chromium plated

parts

paints

paint strippers, based on alkali compounds

or solvents

cement and mortar

water with a small amount of vinegar at an

early stage, in the case of older pollutants -

a solution containing a small amount of

phosphoric acid, followed by water (preferably

demineralised)

iron particles from tools or contact with

structural steel

at an early stage - mechanically, in the

case of pits - etching and passivation pastes

7.2.1 Repairing surface damage

type of damage

method of repair

minor scratches

use a polishing agent (for stainless steel or

chromium) with a soft cloth, suede leather

or nylon sponge

deeper scratches

use the non-wovens for stainless steel

together with water, then apply polishing

agent as follows to restore shine

greater damage, cavities in the material

larger damages can be repaired only by a

specialist through the use of equipment and

abrasives for stainless steel, material losses

require locksmith's and welding interventions

and restoration of the passive layer

17