23833A245

2

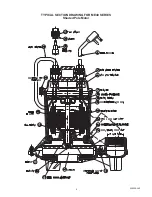

DESCRIPTION AND APPLICATION

ME40

Myers ME40 Series Pumps are single seal units,

automatic or manual, designed for use in effluent

dosing. Septic Tank Effluent Pumping (S.T.E.P.) or

normal sump and general dewatering applications

where higher pressure is required. DO NOT USE FOR

RAW SEWAGE.

When used in effluent dosing or S.T.E.P. applications,

the pump must be installed in a separate tank or

compartment at the discharge side of the septic tank.

NEVER INSTALL PUMP IN MAIN TANK WHERE

SLUDGE COLLECTS.

Impellers are enclosed two-vane type to handle

3/4” spherical solids and are made of engineered

thermoplastic. All pumps have a 1-1/2” NPT

discharge tapping. NOTE: DO NOT OVERTIGHTEN

DISCHARGE PIPE INTO PUMP PLASTIC

DISCHARGE FITTING.

General

These pumps are available in 115 volt or 230 volt,

single phase, 4/10 HP motors. All units are single seal

only, available in automatic or manual with either 10’ or

20’ power cords. All power cords have either 115 volt

or 230 volt grounded plugs.

These pumps are NOT for use in swimming pools or

fountains.

ME40AG

The ME40AG Series Pumps are single seal units

designed for use in continuous run agricultural

evaporative cooling applications. They will run

continuously in elevated temperatures with clean

sump water.

The wetted pump components are the same as

already described for the ME40 series.

AIR LOCKING

A sump pump is said to be air locked if water traps air

in the pump and it cannot get out, thus preventing the

pump from operating.

The ME40/ME40AG pumps have a 1/16” air vent hole

in the impeller chamber to let out trapped air. If this

hole becomes plugged, the pump may air lock. As

a secondary precaution a 1/8” hole should be drilled

in the discharge pipe below the check valve. The

check valve should be 12 to 18 inches above pump

discharge. Do not put check valve directly into pump

discharge opening.

PACKAGING

Each pump is packaged separately in a carton marked

with a catalog number and Myers engineering number.

Catalog

Engineering

Cord

No.

No.

HP

V Ph Lgth.

Type

ME40A-11

25300D000

4/10 115 1

10’

Auto

ME40M-11

25300D001

4/10 115 1

10’

Manual

ME40AC-11

25300D010

4/10 115 1

20’

Auto

ME40MC-11

25300D011

4/10 115 1

20’

Manual

ME40AC-21

25300D012

4/10 230 1

20’

Auto

ME40MC-21

25300D013

4/10 230 1

20’

Manual

ME40P-1

25300D900

4/10 115 1

10’

Auto

ME40PC-1

25300D901

4/10 115 1

20’

Auto

ME40P-2

25300D902

4/10 230 1

10’

Auto

ME40PC-2

25300D903

4/10 230 1

20’

Auto

ME40AG-11

27234D001

4/10 115 1

20’

Manual

ME40AG-21

27234D002

4/10 230 1

20’

Manual

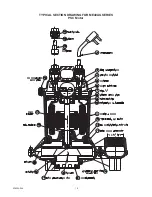

LEVEL CONTROLS

All pumps must use sealed level control switches for

automatic operation. All automatic pumps have built-

in level control float switches. The power cord has a

GROUND PIN that plugs into a grounded receptacle.

The grounded receptacle cannot be used in the wet

sump or basin due to DANGER of current leakage.

Manual pumps can be made automatic with MLC or

MFLC controls with a series plug. Plug the MLC or

MFLC witch cord series plug into a proper voltage

GROUNDED RECEPTACLE. Then plug the pump

cord plug into the back of the switch cord series plug.

NOTE: The float control must be tethered a minimum

4” to pump or discharge pipe. Control must float free

from pump and basin wall.

On all duplex units or simplex installations with

additional options like high water alarm, the power

cord plug must be cut off and wired into a control

panel or into a sealed junction box if used in wet sump

or basin. The AWS-1 control also acts as a sealed

junction box for connecting power cord to pump cord.

NOTE: The ME40 sump/effluent pump can be easily

changed from one style, automatic or manual, to the

other by only interchanging the plug ends of the float

control with the manual plug. The ball float must be

tethered with a cable clamp, as

shown. DO NOT REMOVE THE

MOTOR CAP.

The ME40P pumps have a

mechanical (mercury free) float

switch with a 10’ or 20’ cord with a

115 volt or 230 volt piggyback

plug with the switch mounted to

the pump. Plug the switch cord

plug into a proper voltage, properly

grounded outlet and plug the

power cord into the back of the

switch cord and tape the cords to

the discharge pipe every 12”.