5

and charge housing with about 10 psi of

air. Be sure air is dry. Do not use air line

where water may be trapped in the line.

Submerge complete unit under water

and check for leaks.

Refill motor chamber with oil. Use high

grade transformer oil or Hydromatic

special submersible oil. Fill chamber until

oil covers top of the windings. Leave

air space in the top for expansion. Use

Permatex on plug threads.

Replace Seals and Bearings:

Drain all oil from motor chamber and seal

chamber as described.

Remove motor housing as described.

Remove bolts that hold seal chamber to

pump housing. Use back-off screws to

break loose. With hardwood block, tape

end of impeller to loosen from shaft.

When free, remove impeller from shaft.

Lift rotating assembly (rotor, shaft and

impeller) from pump case and place

horizontally on bench.

Impeller removal — Hold motor and

remove bolt and washer from impeller

end of shaft. Impeller is threaded to

the shaft, so tap face of impeller with

hardwood block to free threads. Holding

rotor, turn impeller with hardwood block

to free the threads. Holding rotor, turn

impeller counterclockwise as thread is

right-hand.

Remove lower seal spring and pry out

seal with screwdriver.

To remove seal housing, take out socket

head bolts and using bolts in back of

holes, pry plates loose. This will force out

lower seal if not already removed.

Remove snap ring that holds upper seal.

Pull seal if it is free. If not free, it can be

forced off when shaft is removed.

Remove four bolts that hold bearing

housing in place. Set assembly in

upright position and bump end of shaft

on hardwood block. This will push the

bearing from the housing and will force

upper seal from shaft.

Use bearing puller to remove bearings.

Replace with new bearings. Press only

on inner face of bearing when replacing.

Pressing on outer face can damage the

bearing.

IMPORTANT: Do not use any of the old

seal parts. Replace with all new seals.

Thoroughly clean all castings before

replacing seals.

Examine all O-rings for nicks before

using.

Use Loctite

®

on socket head locking

screw into the end of the shaft.

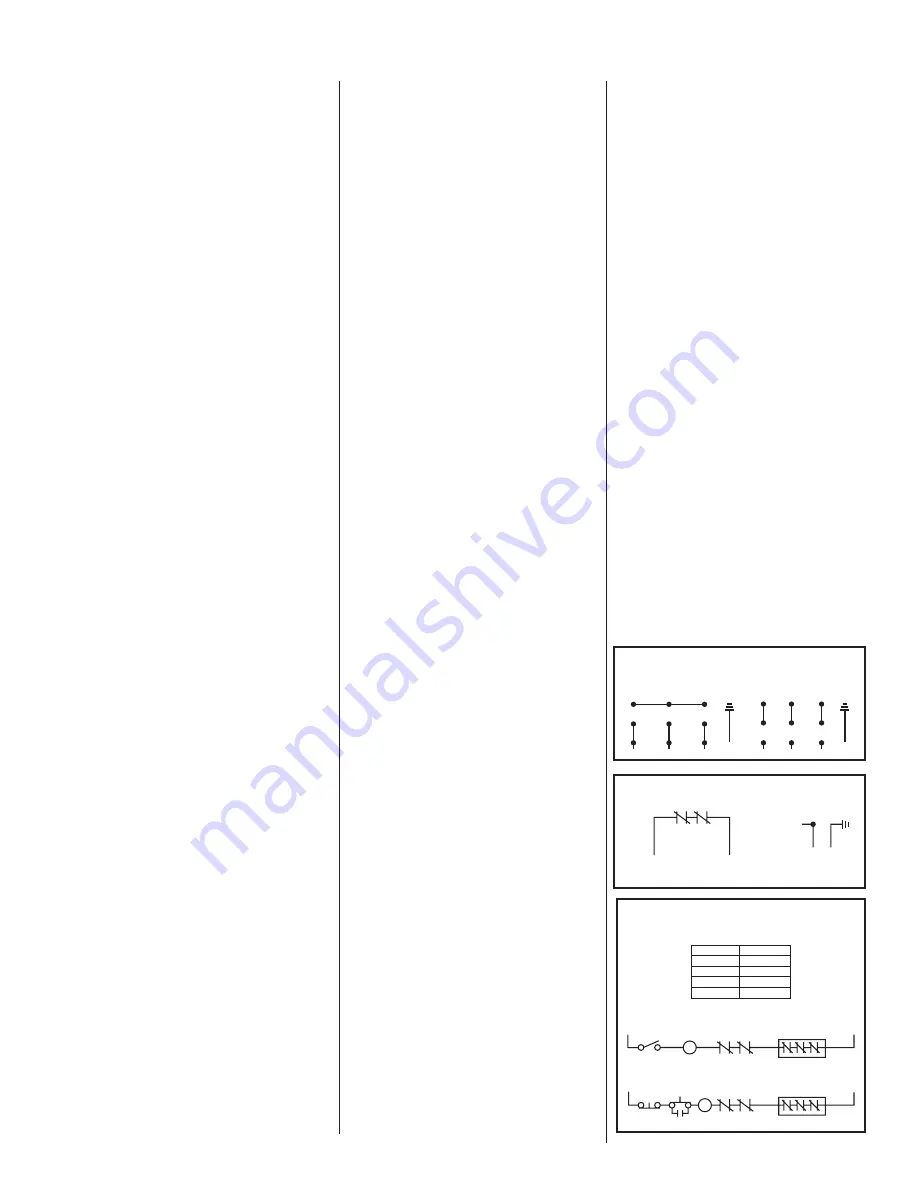

HEAT SENSORS AND SEAL FAILURE CONNECTIONS

FOR ANY VOLTAGE MOTOR

ELECTRODE

HEAT SENSORS

IN MOTOR

WINDINGS

WHITE

BLACK

HEAT SENSORS

SEAL FAILURE

RED

DARK

GREEN

CONNECTION DIAGRAM FOR LEADS IN

MOTOR AND CONNECTION BOX

(Y) WYE MOTOR CONNECTIONS

230 VOLTS

460 VOLTS

GREEN

GREEN

L3

L2

L1

L3

L2

L1

3

2

1

9

8

7

6

5

4

3

2

1

9

8

7

6

5

4

WARNING

BLACK

COIL

ON-OFF

SWITCH

L1

THERMOSTATS

IN SERIES

WHITE

L2

TWO WIRE CONTROL OFFERING AUTOMATIC RESET

THERMOSTATS

IN SERIES

WHITE

L2

BLACK

THREE WIRE CONTROL OFFERING AUTOMATIC RESET

L1

COIL

OL

OL

START

IN CERTAIN APPLICATIONS THE NEC MAY REQUIRE THREE OVERLOAD RELAYS

COLOR

PURPOSE

DARK GREEN

SEAL FAILURE

RED

SEAL FAILURE

BLACK

HEAT SENSOR

WHITE

HEAT SENSOR

WARRANTY IS VOID IF HEAT SENSORS ARE NOT

CONNECTED AS SHOWN (IN SERIES WITH CONTACTOR OIL)

Before refilling chamber with oil, air test

as described above. Refill both chambers

with oil as described above.

Always check all leads with high voltage

or with Megger for grounds before

operating the pump.

Troubleshooting

Below is a list of common problems and

the probable causes:

Pump will not start:

No power to the motor. Check for blown

fuse or open circuit breaker.

Selector switch may be in the Off position.

Control circuit transformer fuse may be

blown.

Overload heater on starter may be

tripped. Push to reset.

Pump will not start and overload

heaters trip:

Turn off power and check motor leads

with Megger or ohmmeter for possible

ground.

Check resistance of motor windings.

All three phases should show the same

reading.

If no grounds exist and the motor

windings check OK, remove pump from

sump and check for clogged or blocked

impeller.

Pump operates with selector switch

in Hand position but will not operate

in Auto position:

This indicates trouble in the float level

control or the alternator relay.

To check for a defective float control,

put selector switch in Auto position and

turn off main power. Put a jump wire on

terminal strip. Turn on power and if pump

starts, trouble is in the float control.

Replace control.

Pump runs but will not shut off:

Pump may be air locked. Turn pump off

and let set for several minutes, then

restart.

Lower float control may be hung-up in

the closed position. Check in sump to be

sure control is free.

Selector switch may be in the Hand

position.

Pump does not deliver proper

capacity:

Discharge gate valve may be partially

closed or partially clogged.

Check valve may be partially clogged.

Raise level up and down to clear.

Pump may be running in wrong direction.

Low speed pumps can operate in reverse

direction without much noise or vibration.

Discharge head may be too high.

Check total head with gauge when pump

is operating. Total head is discharge

gauge pressure converted to feet plus

vertical height from water level in sump to

center line of pressure gauge in discharge

line. Gauge should be installed on pump

side of all valves. Multiply gauge pressure

in pounds by 2.31 to get head in feet.

If pump has been in service for some time

and capacity falls off, remove pump and

check for wear or clogged impeller.

Motor stops and then restarts after

short period but overload heaters in

starter do not trip:

This indicates heat sensors in the motor

are tripping due to excessive heat.

Impeller may be partially clogged giving a

sustained overload but not high enough to

trip overload heater switch.

Motor may be operating out of liquid due

to a failed level control. All Hydromatic

submersible motors can operate for

extended periods out of water without

burning up the winding, but the heat

sensors give motor prolonged life by

controlling winding temperature.

Pump may be operating on a short cycle

due to sump being too small or from water

returning to sump due to a leaking check

valve.

Содержание S3HRC

Страница 7: ...7 Wiring Diagrams...