11

!

!

!

!

!

!

NORMAL SEQUENCE OF OPERATION

On a call for heat, the thermostat will actuate, com-

pleting the circuit to the boiler. In turn, the ignition

systems are activated and ignition will begin.

In the event of a low water condition, an automatic

low water cut-off device will interrupted power be-

tween the low water cut-off and the burner. The

burner will remain off until the low water condition is

corrected, (i.e., manually restore boiler water or

utilize a water feeder device which will automatically

restore water to its normal operating level).

IMPORTANT TO THE INSTALLER -

Before putting

the boiler in operation, test the mechanical low water

cut-off device for proper operation. While burner is

on, open the blow-off valve located in the lower

portion of the cut-off body. This will drain the water

quickly from the cut-off body and break the circuit to

the burner. If it does not, replace control.

WARNING

WATER WILL BE BOILING HOT.

OPERATING INSTRUCTIONS

The venting system should be inspected at the start

of each heating season. Check the vent pipe from

the boiler to the chimney for signs of deterioration by

rust or sagging joints. Repair if necessary.

Remove the vent pipe at the base of the chimney or

flue and, using a mirror, check for obstruction and

verify compliance to the latest revision of the NFPA

211.

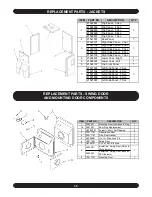

The lever of the pressure relief valve

(Figure 12)

on

the boiler should be operated periodically to make

sure that it is functioning properly.

WARNING

Discharge will be boiling hot water and steam.

The pressure relief valve should open before the

steam pressure exceeds the 15 lb. reading on the

gauge. If this pressure is exceeded and the pressure

relief valve leaks steam when the boiler is operating

at normal pressures, it should be immediately

replaced. Corrosion can build up rapidly at the valve

seat and prevent its functioning as a safety device.

START-UP AND ADJUSTMENT

OF OIL BURNER

(See oil burner instructions for nozzle and electrode setting).

CAUTION

DO NOT SET FIRE VISUALLY.

Instruments are the only reliable method to

determine proper air adjustments. An

improperly adjusted burner causes soot and

high fuel bills because of incomplete

combustion of the fuel oil. This in turn may

require excessive boiler maintenance, service

costs, and in some instances, house cleaning

or redecorating. A competent service

mechanic should be consulted to make the

proper adjustments with a smoke tester, CO

2

indicator, and draft gauge. NOTE: Bacharach

or Dwyer test kits include these instruments.

A. Check oil burner nozzle to make certain it is tight

in adapter. Burner mounting bolts should be tight.

B. Check electrode setting, as they may have been

jarred out of position during transportation.

C. Lubricate burner motor if necessary.

FIGURE 12