4. Using an Allen wrench, loosen the pump coupling

(23) set screw (38) and remove the coupling, thrust

collars and bail bearings (14).

5. Remove pump strainer (15) and suction plate (7).

Use care when withdrawing shaft to

prevent bending or damage. Use

proper support and two men for removal of long,

heavy shaft.

6. Pull out impeller and shaft assembly (1 and 2)

from impeller end of pump.

7. Unscrew impeller nut (40) and remove washer (39).

8. Remove the discharge pipe set screw (36), and

pull the discharge pipe (12) up out of the pump

discharge casing (6). The bottom end of the

discharge pipe is not fastened in any way; it has a

flexible connection sealed by a rubber packing ring

(13).

9. If pump has intermediate bearings (3) which need

replacing, separate the hanger pipes (10).

CLEANING:

Pump parts may be cleaned with petroleum base

solvent if desired. Metal parts (except motor) may be

soaked in solvent if necessary. Use a bristle brush

(not metal or wire) to remove tightly adhering

deposits. Wipe the exterior of motor housing with a

solvent-dampened cloth. Blow parts dry with clean,

dry, compressed air. Clean ball bearings in the

following manner:

Petroleum base cleaning sol-

vents are flammable. Open flame

or smoking by personnel in the vicinity of these

solvents is extremely hazardous and must not be

permitted. Disregard of this Warning can result in

serious bodily harm and could be fatal.

1. Place bearings in wire basket – so there is space

for cleaner to reach all parts.

2. Immerse in Stoddard solvent. Agitate basket until

old grease is thoroughly loosened and can be flushed

out.

3. Place bearing on a screened surface.

4. Using a spray gun with air filter and clean

Stoddard solvent, flush each bearing until all grease

and sludge is removed.

Never spin ball bearings. Spin-

ning

a

dry

ball

bearing

can

cause damage. Spinning any ball bearing by an air

blast can cause bearing to fly apart resulting in

possible fatal injury.

5. Blow solvent out of bearing with dry, filtered air.

6. Lubricate bearings immediately after cleansing

with light spindle oil and place them in a covered

container.

INSPECTION:

Inspect pump parts for cracks, dents,

nicks, scratches or other damage affecting service-

ability or sealing.

CAUTION

Test cleaned and oiled bearings by rotating slowly

with the hands. If worn, rough, noisy, loose or

flatted, replace with new. Do not unwrap new

bearings until ready to be installed.

REPAIR:

Remove burrs, nicks or scratches from

non-critical surfaces with a fine stone or crocus

cloth.

Replace all parts that show wear.

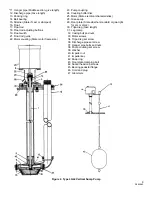

When ordering replacement parts always furnish data

stamped on nameplate attached to the pump. Give

the figure number, index number and part name as

shown on figure 2.

TO REPLACE GUIDE BEARINGS [3, 4, and 5]:

All

guide bearing are originally pressed in at the

factory, being held in place by the tight fit. To

remove the worn bearings they may either be sawed

in half with a steel hack saw blade and collapsed, or

threaded with a 3/4 inch tap and removed with a 3/4

inch bolt shouldered over a pipe sleeve.

New guide bearings should be pressed or lightly

tapped in place using a block of wood as a buffer.

When installing the bottom bearing (5) in pump

discharge casing, be sure that the end of bearing

nearer the impeller is approximately 1/8 inch within

the housing so that the snap ring (42) on the shaft

will not come in contact with the bearing.

WARNING

Refer motor to a repair shop author-

Ized by the motor manufacturer for

repairs. It is not recommended tat user attempt to

make repairs on this type motor under any

circumstances. Attempt to repair motor by unauth-

orized personnel voids manufacturer’s warranty.

CAUTION

ASSEMBLY:

To assemble the pump, reverse the

disassembly procedure but observe the following

precautions:

1. Be sure not metal filings or cuttings are left in the

hanger pipe. Flush out well with solvent before

inserting shaft.

WARNING

2. Before reinstalling, clean the radial thrust bearing

collars thoroughly in solvent. Be sure the collars are

placed above and below the ball bearing.

10

2899982