1

SECTION I

GENERAL INFORMATION

This manual covers the installation, operation and maintenance of Patterson Pump vertical inline pumps.

The pump is a centrifugal, single stage close-coupled type. When properly installed and when given

reasonable care and maintenance, centrifugal pumps should operate satisfactorily for a long period of

time. Centrifugal pumps use the centrifugal force principal of accelerating the liquid within a rotating

impeller, and then collecting it and converting it to pressure head in a stationary volute.

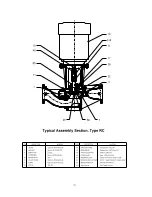

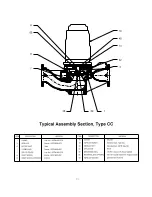

The pump consists of two assemblies:

1.

Volute assembly or stationary part

2.

Rotating element or moving part

The back pullout design casing allows removal of the impeller and rotating element without disturbing

suction and discharge piping. The suction and discharge flanges are on a common centerline 180

degrees apart. Suction and discharge flanges are drilled and tapped for gauge connections. The volute

is drilled and tapped on the underside for complete pump drain. Casing wear rings are provided as

standard equipment.

SECTION II

STORAGE & PROTECTION

All pumps are shop serviced and ready for operation when delivered, but there is occasions when

considerable time elapses between the delivery date and the time the pump is put into operation.

Equipment, which is not in service, should be kept in a clean, dry area. If equipment is to be stored for

long periods of time (six months or more), the following precautions should be taken to insure that the

equipment remains in good condition.

1.

Unpainted-machined surfaces, which are subject to corrosion, should be protected by

some corrosive resistant coating.

2.

The shaft should be rotated 10 to 15 revolutions by hand periodically in order to spread

the lubricant over all the bearing surfaces. Suitable intervals are from one to three

months, depending on atmospheric conditions, etc. In order to insure that the pump shaft

does not begin to sag, do not leave the shaft in the same position each time.

3.

Space heaters on motors and controllers should be connected and fully operable if

atmospheric conditions approach those experienced in operation. Consult instruction

manuals for other precautions concerning storage of individual components of pumping

unit.

4.

Fresh lubricant must be applied to bearings upon removal of equipment from storage.

Refer to motor manual.