Parker Hannifin Corporation

Actuator Division

Wadsworth, Ohio USA

62

Catalog AU03-0900P-2/NA

Maintenance Instructions

Maintenance Instructions and Service

RC Series

7)

Test cylinder for audible leakage.

8)

Install outer band through the piston

carriage and into each end cap above the

band spacer. Position the band so no band

material protrudes from the face of either

end cap.

9)

Place carriage on piston.

10) Install carriage bolts and tighten on

each end of carriage.

11) Install carriage support rods (sym.

#13 if applicable) or carriage spacer #13A

(25mm bore).

12) Install band wipers with button head

screws. (On 25mm and 32mm bores with

double carriage mounting, install thinner 2

band wipers on inner ends of carriages.)

13) Install outer band set screws into band

clamp at each end and tighten to the rec-

ommended torque value

(Table C).

2)

Install the band clamp (sym. #22) on

each end cap with the flat head fasteners

(sym. #15). Tighten fasteners to the recom-

mended torque value

(see table C).

3)

If the outer band set screws (sym. #6)

have not already been removed, remove

them now.

4)

Insert the band clamp spacers (sym.

#16) into each end cap with the set screws

(sym. #8) pre-installed and with the hex

side of the set screws facing up.

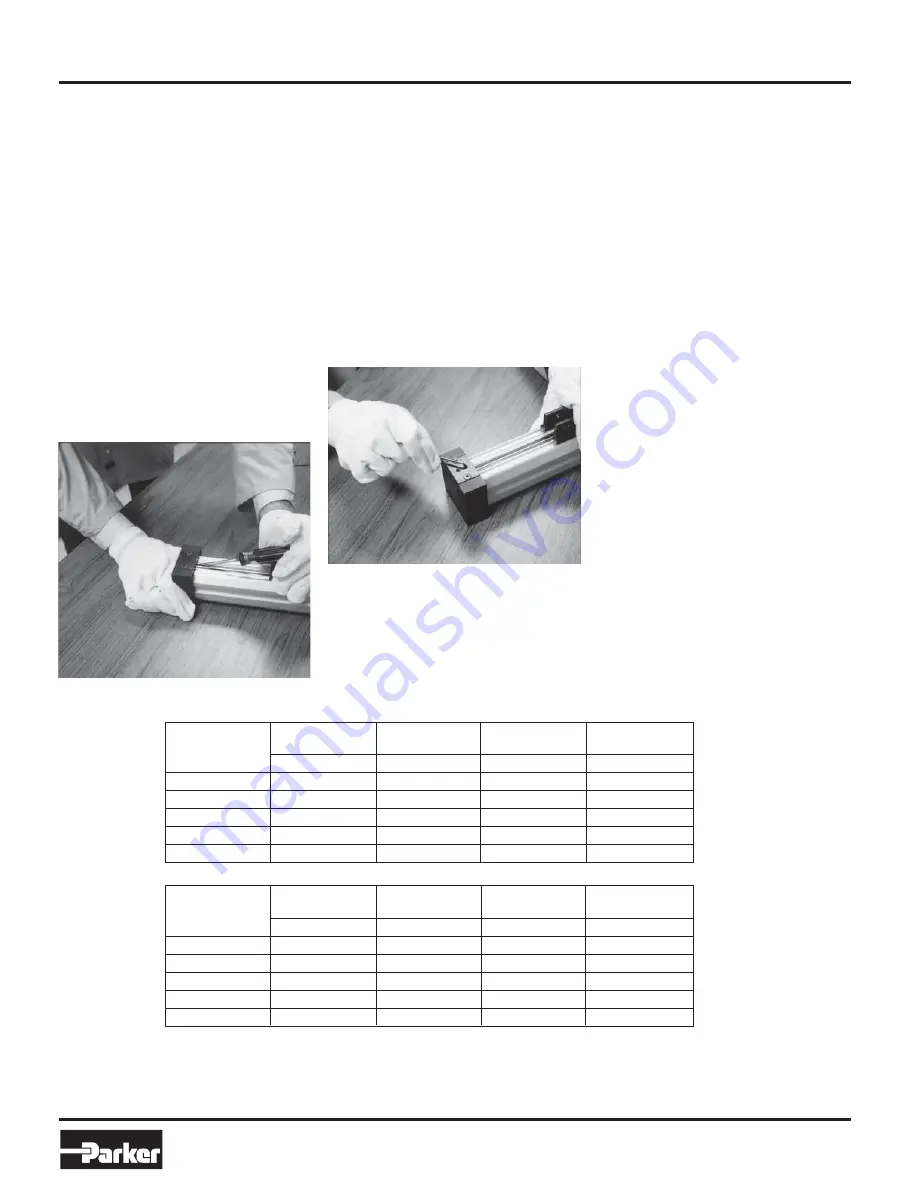

5)

Insert a hex wrench through the outer

band set screw holes

(Photo #11) to

access the set screws in the band spacer.

6)

Tighten the inner band set screws at

each end to the recommended torque

value

(Table C).

Photo #11

3)

Repeat the preceding two steps to

install the opposite end cap.

4)

Place the cylinder assembly on a flat

surface so the end caps are aligned.

5)

Insert the end cap mounting screws

(sym. #9) at both ends and tighten to the

recommended torque value

(see Table C).

C) Final Assembly

1)

Using a thin flat blade screwdriver,

remove the slack of the inner band by

pushing the slot at each end

(Photo #10).

NOTE: The goal is not to tension the band,

merely to eliminate any slack. Use of

excessive force may cause the band to

move out of position and/or band

damage.

Photo #10

End Cap

Band Clamp

Inner Band

Outer Band

Bore

Screws

Screws

Screws

Screws

Size

Sym. #9

Sym. #15

Sym. #8

Sym. #6

25mm

35 + 5

10 + 2

10 + 5

10 + 5

32mm

35 + 5

10 + 5

10 + 5

10 + 5

40mm

60 + 10

15 + 5

10 + 5

10 + 5

50mm

40 + 10

15 + 5

10 + 5

10 + 5

63mm

70 + 10

15 + 5

10 + 5

10 + 5

RC Series Rodless Cylinder Torque Values (Kg cm)

End Cap

Band Clamp

Inner Band

Outer Band

Bore

Screws

Screws

Screws

Screws

Size

Sym. #9

Sym. #15

Sym. #8

Sym. #6

25mm

40 + 6

12 + 2

12 + 6

12 + 6

32mm

40 + 6

12 + 6

12 + 6

12 + 6

40mm

69 + 12

17 + 6

12 + 6

12 + 6

50mm

46 + 12

17 + 6

12 + 6

12 + 6

63mm

81 + 12

17 + 6

12 + 6

12 + 6

Table C

RC Series Rodless Cylinder Torque Values (inch - pounds)

Note: Rodless cylinder

fasteners should be

properly torqued using a

calibrated torque

wrench. Torquing of the

end cap fasteners

should be performed

first using the opposite

corner sequencing

technique to approxi-

mately 75% of the final

torque value shown in

the table to the left.

Then, continuing the

opposite corner

technique, torque to

the final value.