18

Parker Hannifin Manufacturing Germany GmbH & Co. KG

Pump & Motor Division Europe

Chemnitz, Germany

Electro hydraulic proportional controls version 45 for

axial piston pumps, PV series

Bulletin MSG30-3254-INST/UK

Installation and setup manual

9.2 Basic adjustment LVDT

The inductive position transducer for displace-

ment feedback (LVDT) and the compensator

valves are factory preset and the settings are

secured. New or readjustment is only neces-

sary after repair.

LVDT for displacement feedback:

Prior to a basic setting the adjustment of the

armature length is to be checked / readjusted

(see figure 16). The exact dimension for this

setting is given in table 4:

Size

Size

Serie 45

1

PV016-028

73.5

2

PV032-046

73.5

3

PV063-092

75.0

4

PV140-180

75.0

5

PV270

75.0

6

PV360

75.0

Table 4:

setting dimensions LVDT core

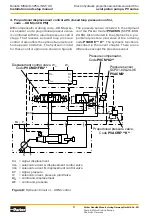

Figure 16:

Setting dimension A for LVDT armature

The adjustment is secured by a removable glue.

A new setting again has to be secured to avoid

uncontrolled re-setting.

At full upstroked pump the mechanical adjust-

ment can be verified: The voltage at the LVDT

output (pin 25 at the control module) should

have a value as given in the table below (± 0,2 V).

Zero adjustment:

Next the zero adjustment of the LVDT is to be

checked. The LVDT and the solenoid of the

displacement control valve are to be connected

according to chapter 9 to the electronic control

module.

Size

voltage

size

voltage

PV016

6.34 V

PV063

7.12 V

PV020

6.06 V

PV080

6.48 V

PV023

5.87 V

PV092

6.10 V

PV028

5.50 V

PV140

5.24 V

PV032

6.40 V

PV180

3.83 V

PV040

5.70 V

PV270

4.06 V

PV046

5.43 V

PV360

4.06 V

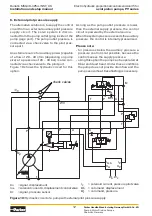

Protection plug

with o-seal

Zero adjustment

(sealed)

Do not touch!

electrical

connection

Figure 17:

Iinductive positon transducer (LVDT),

outside view

At running pump the command for the displace-

ment is to be set to 0 and the pressure relief valve

of the circuit / test rig has to be set to a pressure

> 25 bar. All other connections / valves in the

hydraulic circuit are to be closed.

The pump then will down stroke to deadhead

at the minimum pump compensating pressure

(10 ± 2 bar). By setting the zero adjustment

potentiometer (see figure 17) at the LVDT the

diagnosis output of the control module is to

be set to 0 V, as the actual displacement is the

minimum displacement that can be controlled.

After adjustment the potentiometer

must

be

sealed again.

MAX-adjustment:

Next the command for the displacement is to

be increased, until the maximum displace-

ment of the pump is reached. That can either

be monitored by using the diagnosis output or

a flow meter at the pump outlet. The maximum

displacement is reached, if the displacement /

flow does not further increase, even when the

input command is still raised.