5

Refrigerating Specialties Division

valves isolating such sections should be marked,

warning against accidental closing, and must not be

closed until the liquid is removed. Check valves

must never be installed upstream of solenoid valves,

or regulators with electric shut-off, nor should hand

valves upstream of solenoid valves or downstream of

check valves be closed until the liquid has been

removed. It is advisable to properly install relief

devices in any section where liquid expansion could

take place.

Avoid all piping or control arrangements which might

produce thermal or pressure shock.

For the protection of people and products, all refriger-

ant must be removed from the section to be worked

on before a valve, strainer, or other device is opened

or removed.

Flanges with ODS connections are not suitable for

ammonia service.

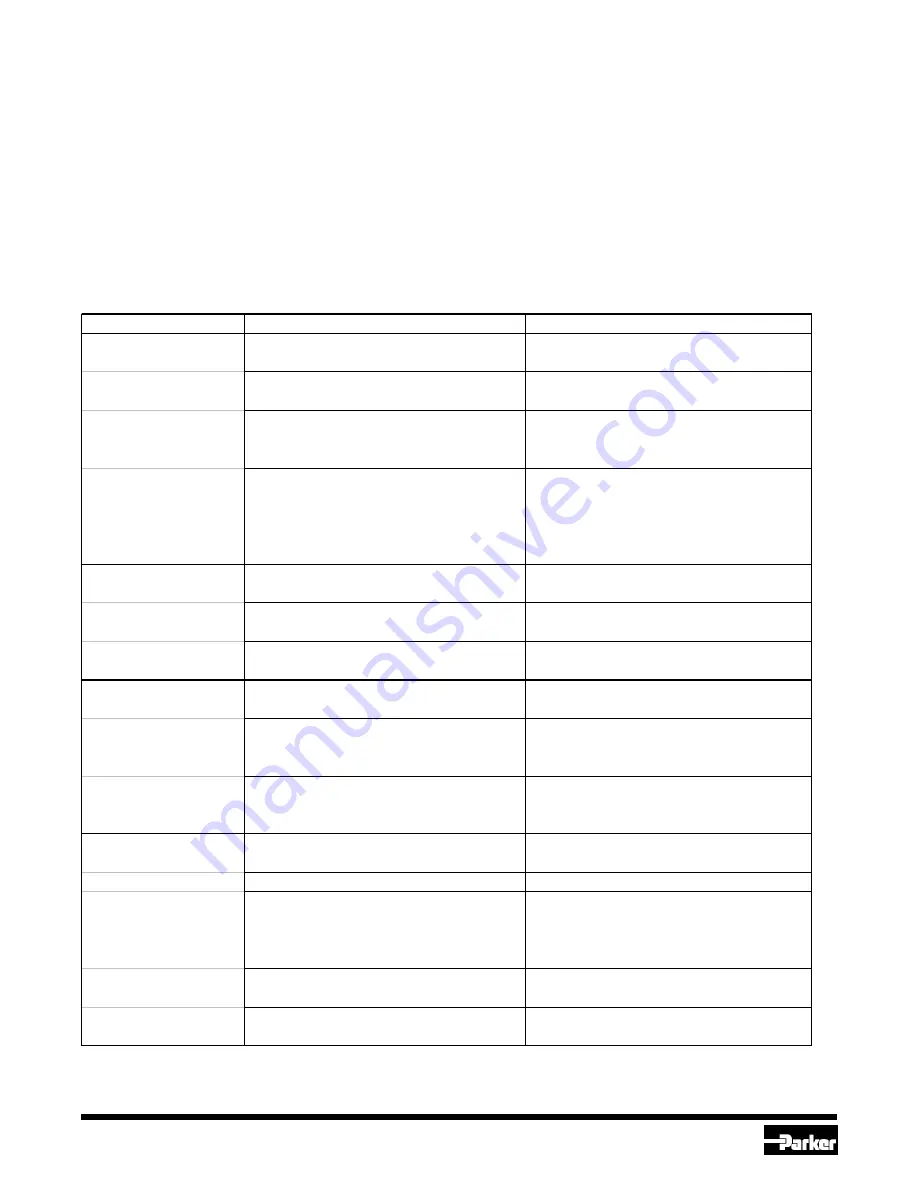

SYMPTOM

PROBABLE REASON

CORRECTION

Regulator does not

shut off flow

Diaphragm or seat dirty, damaged or

frozen

Clean or replace. Clean strainer

Diaphragm follower stuck or damaged

Clean or replace. Install follower

carefully

Piston jammed with excess dirt

Remove and polish piston and bore

with crocus cloth. Clean valve and

strainer

Modulating plug leaking due to excess

dirt or damaged

Clean or replace. If used on liquid,

check for erosion due to excessive

flash gas by subcooling or by reducing

pressure drop across valve by providing

restriction at valve outlet.

Regulator does not

open

Pressure Regulator Diaphragm

ruptured or badly deformed

Replace. Make sure 2 diaphragms are

installed.

Diaphragm follower stuck, damaged or

frozen

Clean or replace. Install follower

carefully

Piston worn, too much clearance

Replace piston. Check for reason. If

used or liquid, check for flash gas.

Regulator Operation

erratic

Diaphragm or seat dirty, damaged.

Clean or replace. Clean strainer

Diaphragm follower has dirt on the

outside diameter or outside diameter is

damaged.

Clean or replace

Regulator too far oversized.

Check load. Replace with smaller

regulator or investigate use of Reduced

Capacity Plug Kit.

Pressure drop across

regulator too high

Inlet or outlet restricted

Check for restriction. Clean strainer.

Regulator too small

Replace with proper size regulator

Large amount of flash gas in liquid line Reduce flash gas by subcooling.

Reduce line restriction by increasing

line size, particularly at the regulator

outlet. Replace with larger regulator.

High pressure drop causes high rate of

expansion of gas at regulator outlet

Increase pipe size at the outlet of the

regulator

Regulator does not open all the way.

Check piston for wear. Replace, if

needed.