12

Parker Hannifin Manufacturing Germany GmbH & Co. KG

Pump & Motor Division Europe

Chemnitz, Germany

Axial Piston Pump

Series PV, series 47 and higher

Bulletin MSG30-3245-INST/UK

Installation manual

10. Compensator accessories

10.1 Pressure relief pilot valve, code

PVAC1P...

The pressure relief pilot valve code PVAC1P... is

optimally tuned for the requirements of the com-

pensator valves of the series PV. It has a mounting

interface NG6 according to DIN 24340 and can be

mounted directly on top of all compensator valves

with the topside mounting interface.

Such a valve is only necessary for the compensa-

tors with elbow manifold (...MT1 and ...UDR) and

for the versions without integrated pressure pilot

cartridge (compensator code ends with..Z). Al

other versions include an integrated pilot valve.

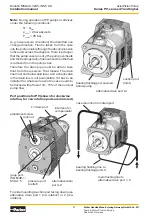

lock nut

set screw

After loosening the lock nut SW13 an adjustment

of the compensating pressure for the pump is

possible in a range of approx. 20 bar up to 350 bar.

The pressure pilot valve is also available with a

DIN lock.

10.2 Multiple pressure pilots PVAC1E...,

PVAC2P..., PVAC2E... und PVAC2M...

For multiple pressure pilots, codes PVAC2P...,

PVAC2E... and PVAC2M... a sandwich valve with

two direct-action pressure cartridge valves is used

to pilot the pump.

Adjustment A: tolerance compensation for opti-

mized performance; done at pilot cartridge.

Adjustment B: maximum pressure setting; done

at integrated pressure pilot valve.

Constant horse power curve with adjustment

At the adjustment screw of the horse power pilot

valve a basic adjustment of the horse power com-

pensator can be made. After loosening the lock

nut (self sealing nut) the compensator control

curve can be moved by turning the adjustment

screw (adjustment A in the diagram left). This

adjustment, done to meet the required constant

input horse power curve, is already made during

the factory test and should be modified only in

exceptional cases.

To adjust the correct constant horse power curve

a measuring device is required. An output power

measurement requires pressure and flow meter-

ing. An input power measurement requires torque

and speed measurement or a measurement of

the electric motor current.

Note:

For horse power control the load sensing

differential is set to 15 ± 1 bar. Any change will

result in a deviation from the horse power setting.

Note

: The setting is very sensitive, 0.1 mm

change of the spindle changes the pressure ap-

proximately 20 bar.