OPERATION AND MAINTENANCE MANUAL | ENG_OMM_AlphaGrinder_P01 | 10th July 2019

© Pandrol 2020

13

of

24

4. Installation and Use

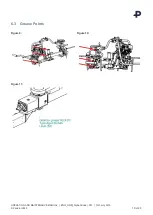

4.1 Installing grindstone

The engine must be

switched off

when mounting/dismounting the grindstone or when the machine is resting on

the ground.

Dismounting grindstone

1. Place the grinding machine stable and suitable for replacing the grindstone.

2. Remove the cover around the grindstone, 3 screws M8 M6S

3. Lock axle with key size 24

4. Unscrew the adapter for the grindstone with key size 24 from the axle.

5. Release the adapter from the grindstone and replace/fit the new.

Mounting the grindstone

Follow the description above in reverse order.

4.2 Installing on rail

The engine has to be switched off when mounting/dismounting the machine or when the machine is

resting on the ground.

Inspect the Alpha grinder to make sure there are no damages and that it is completely free from defects.

4.3 Adjustments

Check rail width, allowed play 5-15 mm.

Check the play between rail and grindstone, clearance has to be at least 1 mm. Adjust with wheel/knob.

4.4 Start the motor/machine

Make sure all safety information have been read before starting the machine.

Ensure all pre checks have been conducted. The machine must only be started on the track.

2. Start with the machine in the flat position and with the grindstone in the horizontal position.

3. Check the clearance between the grindstone and the rail. The grindstone must be clear from the weld.

4. Check that the protection cover is in place and is folded down.

5. Check that the emergency stop is extended.

6. Start the engine by holding the grip and pulling the start cord until motor starts, allow the cord to retract.

4.5 Operation Grinding

Make sure all safety information have been read before using the machine.

7. Set the grinder to max.

8. Gently lower the grindstone over the grinding point on the rail. until it fires fire from the grinding point.