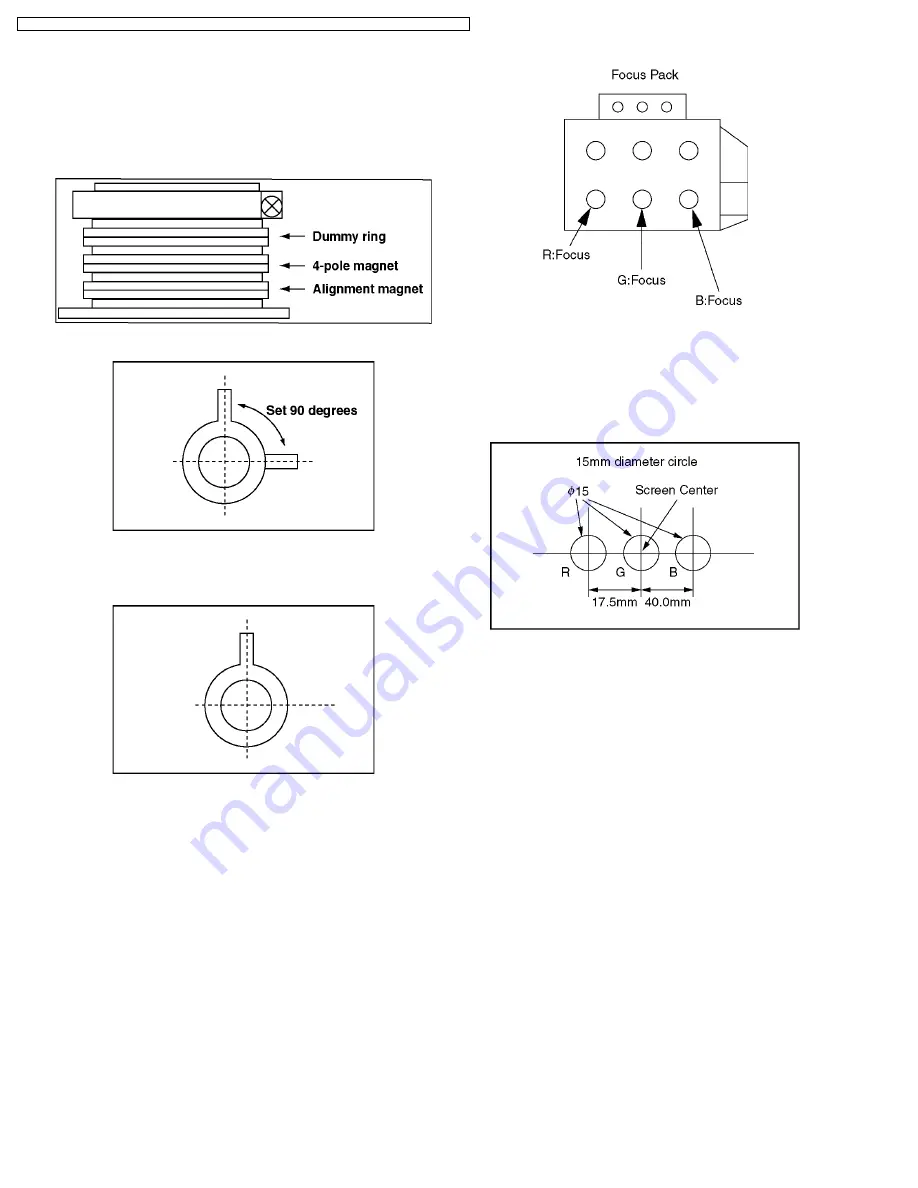

Preparation:

1. Receive an cross hatch pattern with dots (pincushion).

2. Loosen the centering magnets screws.

3. Position the longer tab of the four-pole magnet to 90

degrees (uncorrected position).

VM Coil with focus correction magnet

4-pole magnet

4. Position the long tab of all alignment magnets and of the

dummy ring together in an uncorrected position.

Alignment magnet (or dummy ring)

Procedure:

1. Receive an cross hatch pattern with dots.

2. Cover the Red, Blue CRT lens, projecting Green only.

3. Turn the green electrical focus adjustment VR (on focus

pack) fully counterclockwise and note the position of the

dots at the center of the picture.

4. Turn the green electrical focus adjustment VR fully

clockwise.

5. Adjust the four pole magnets until the shape of the dot

at the center of the screen is circular.

6. Adjust for best green electrical focus with green

electrical focus adjustment VR.

7. Cover the Green, Red CRT lens, projecting Blue only.

8. Repeat step 4. ~ step 6. for blue electrical focus.

9. Cover the Green, Blue CRT lens, projecting Red only.

10. Repeat step 4. ~ step 6. for red electrical focus.

11. Receive an monoscope pattern.

12. Cover the Red, Blue CRT lens, projecting Green only.

13. If the center of the monoscope pattern is not inside the

15mm circle, shown in below, adjust the centering

magnets. Repeat the alignment magnet adjustments

and four pole magnet adjustments (step 1. ~ step 6.)

Centering magnet adjustment

14. Cover the Green, Blue CRT lens, projecting Red only.

15. Repeat step 13. for the red.

16. Cover the Green, Red CRT lens, projecting Blue only.

17. Repeat step 13. for the blue.

18. Following adjustments, fix the centering magnets of DY,

dummy rings of VM coil, four pole magnets of VM coil

and the alignment magnets of VM coil to prevent them

from moving.

7.5.

Alignment magnet Adjustment

22

TX-51P800X / TX-51P800HM / TX-51P800HQ / TX-43P800X / TX-43P800HM / TX-43P800HQ / TX-43P800HZ

Содержание TX-43P800HM

Страница 16: ...16 TX 51P800X TX 51P800HM TX 51P800HQ TX 43P800X TX 43P800HM TX 43P800HQ TX 43P800HZ ...

Страница 17: ...6 3 Option Descrition 17 TX 51P800X TX 51P800HM TX 51P800HQ TX 43P800X TX 43P800HM TX 43P800HQ TX 43P800HZ ...

Страница 18: ...18 TX 51P800X TX 51P800HM TX 51P800HQ TX 43P800X TX 43P800HM TX 43P800HQ TX 43P800HZ ...

Страница 19: ...19 TX 51P800X TX 51P800HM TX 51P800HQ TX 43P800X TX 43P800HM TX 43P800HQ TX 43P800HZ ...

Страница 43: ...43 TX 51P800X TX 51P800HM TX 51P800HQ TX 43P800X TX 43P800HM TX 43P800HQ TX 43P800HZ ...