5.2 MECHANICAL ADJUSTMENT PROCEDURE

No.

Item

Equipment

Fig.

Procedure

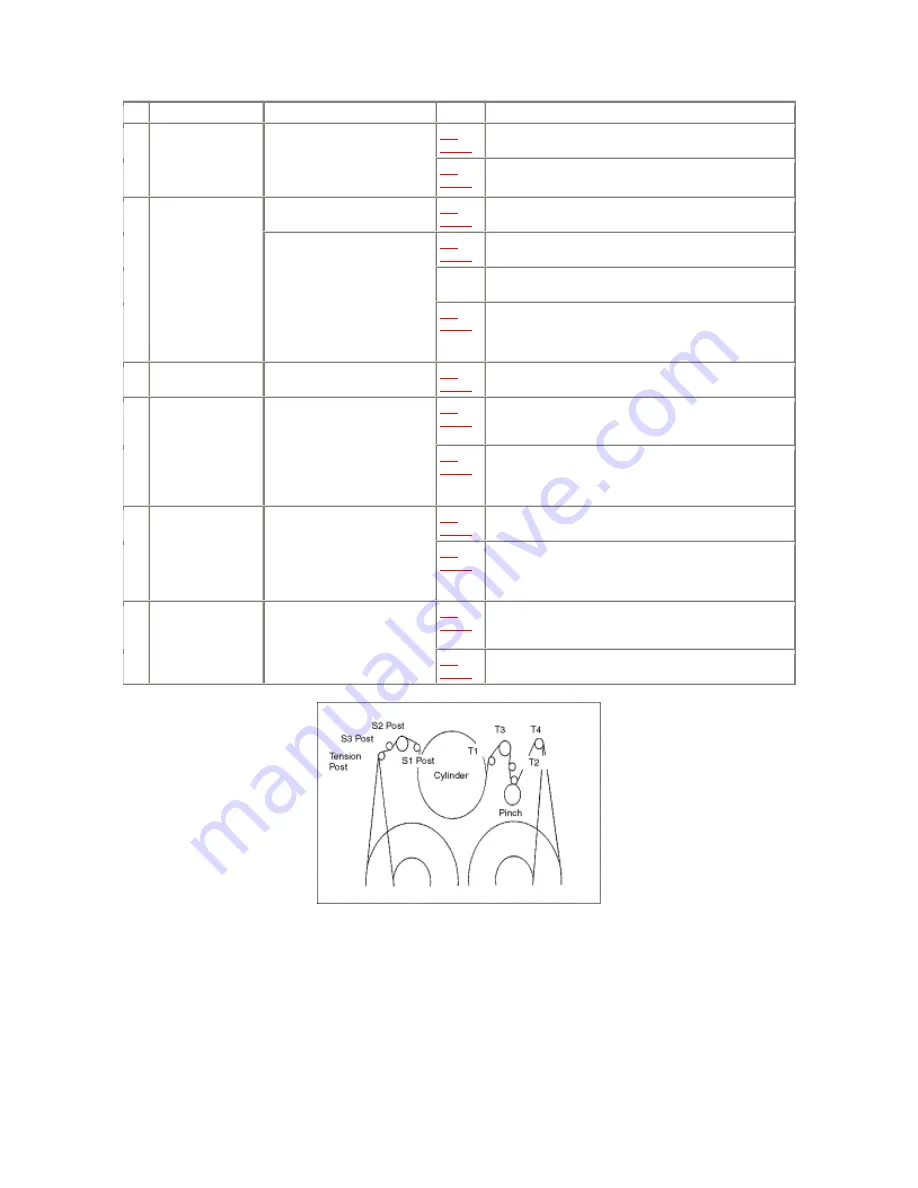

1) Confirm each post position in playback mode.

1

Confirmation of Tape

Running

1. Alignment Tape

(PAL: VFM3110EDS/NTSC:

VFM3010EDS)

2. Post Adjustment

Driver(VFK1278)

2) Confirm condition of tape regulation in playback & review

mode.

1.Tatsujin system(Refer to Fig.)

1) Set up Tatsujin System.

2) Connect Envelope Detector Board between Measuring Board &

Oscilloscope.

--

3) Remove Adjustment Cover.

* Location for Adjustment Cover depends on Models.

2

Linearity Adjustment

2. Alignment Tape

(PAL: VFM3110EDS/NTSC:

VFM3010EDS)

3. Envelope Detecor Board

(VFK1641)

4. Post Adjustment Driver

(VFK1278)

4) Playback the Alignment Tape and adjust S2 & T3 posts by

Screw Driver until wavefom becomes flat.

After adjustment, B.E.R. should be confirmed by Electrial

adjustment on the "Tatsujin".

3

Confirmation of

B.E.R. Value

1.Tatsujin system(Refer to Fig.)

1) Refer to Electrical Adjustment on the "Tatsujin".

1) Slide sensor pin to Capstan shaft.

After touching,if OK, LED should be lit.

* Do not touch when you confirm LED lit or not.

4

Capstan tilt

Adjustment

1. Capstan Tilt Adj. Jig(VFK1638)

2. Small Phillips Screw Driver

2) If Ng, Capstan tilt should be adjusted.

a) Tighten screw (A) until LED is lit.

b) Loose screw (B) until LED is not lit.

c)Tightenscrew (A) unti-clockwise until LED is lit .

1) Adjust S3 screw as Evvelope becomes flat.

5

S3 Base adjustment

1. Post Adjustment

Driver(VFK1278)

2) Tighten a screw 180 degree as "ENV 1".

3) Loosen a screw as ENV 2.

4) Tighten a screw until ENV becomes flat as ENV 3 and tighten

a screw 180 degree again.

1) Make Review Position.

* Set Loading mode and then,stop Pinch Roller & Capstan shaft is

touched.

6

Sub Chassis

Adjustment

1. Small Phillips Screw Driver

2) Loosen a screw.

After fixing a shaky Sub Chassis,then tighten a screw.

Fig. AD1-1

Fig. AD1-2

Содержание Mini DV

Страница 2: ...1 MECHANICAL PARTS LOCATION 1 1 UPPER SIDE ...

Страница 3: ...1 2 BOTTOM SIDE 1 3 SENSOR POSITION ...

Страница 6: ...3 DISASSEMBLY PROCEDURE 3 1 PREPARATION FOR DISASSEMBLY ...

Страница 9: ...Fig D2 1 Fig D2 2 Fig D2 3 ...

Страница 10: ...Fig D3 1 Fig D3 2 Fig D3 3 ...

Страница 11: ...Fig D4 1 Fig D4 2 Fig D4 3 ...

Страница 12: ...Fig D5 1 Fig D5 2 Fig D6 1 ...

Страница 13: ...Fig D6 2 Fig D7 1 Fig D7 2 ...

Страница 14: ...Fig D7 3 Fig D8 ...

Страница 15: ...Fig D9 Fig D10 Fig D11 Fig D12 Fig D13 ...

Страница 16: ...Fig D14 Fig D15 Fig D16 Fig D17 1 ...

Страница 17: ...Fig D17 2 Fig D18 1 Fig D18 2 ...

Страница 18: ...Fig D19 Fig D20 1 Fig D20 2 ...

Страница 19: ...Fig D20 3 Fig D21 ...

Страница 23: ...Fig W1 3 Fig W1 4 Fig A1 ...

Страница 24: ...Fig A2 1 Fig A2 2 Fig A2 3 ...

Страница 25: ...Fig A2 4 Fig A3 Fig A4 ...

Страница 26: ...Fig A5 1 Fig A5 2 ...

Страница 27: ...Fig A6 Fig A7 Fig A8 ...

Страница 28: ...Fig A9 Fig A10 1 Fig A10 2 ...

Страница 29: ...Fig A11 Fig A12 Fig A13 ...

Страница 30: ...Fig A14 Fig A15 1 Fig A15 2 ...

Страница 31: ...Fig A15 3 Fig A16 1 Fig A16 2 ...

Страница 32: ...Fig A17 1 Fig A17 2 Fig A17 3 ...

Страница 33: ...Fig A17 4 Fig A18 1 Fig A18 2 ...

Страница 34: ...Fig A18 3 Fig A19 1 Fig A19 2 ...

Страница 35: ...FIg A19 3 Fig A20 1 Fig A20 2 ...

Страница 36: ...Fig A20 3 Fig A21 1 Fig A21 2 ...

Страница 39: ...Fig AD2 1 Fig AD2 2 Fig AD2 3 Fig AD4 1 Fig AD4 2 ...

Страница 40: ...Fig AD5 1 Fig AD5 2 Fig AD6 1 ...

Страница 41: ...Fig AD6 2 ...

Страница 42: ...6 EXPLODED VIEWS 6 1 Q1 Q2 VCR MECHANISM SECTON 1 ...

Страница 43: ...6 2 Q1 Q2 VCR MECHANISM SECTION 2 ...

Страница 44: ...6 3 Q3 VCR MECHANISM SECTION 1 ...

Страница 45: ...6 4 Q3 VCR MECHANISM SECTION 2 ...