ABP8

141

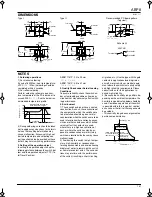

DIMENSIONS

Type I

Type II

Recommended PC board pattern

(Top view)

Schematic

SPST-NO

C

L

3.4

.134

3.4

.134

2.3

.091

FP

3.7 max.

.146

OP

3.3

±

0.2

.130

±

.008

TTP

2.3 max.

.091

1.2

.047

0.15 max.

.006

0.25

.010

C0.1

.004

1.5

.059

1.0

.039

0.3

.012

1.0

.039

0.2

.008

1.2

±

0.05

dia.

.047

±

.002

dia.

0.8 dia.

.031 dia.

Terminal #3

Terminal #1

Terminal #2

C

L

2.3

.091

2.9

.114

FP

4.9 max.

.193

OP

4.5

±

0.2

.177

±

.008

TTP

3.5 max.

.138

0.15 max.

.006

0.25

.010

C0.1

.004

0.2

.008

1.2

±

0.05

dia.

.047

±

.002

dia.

0.8 dia.

.031 dia.

Terminal #3

Terminal #1

Terminal #2

3.7

.146

1.3 dia. hole

+

0.2

−

0

.051 dia. hole

+

.008

−

0

1.5

.059

0.7

.028

1.1

.043

1.1

.043

Terminal #3

Terminal #1

Terminal #2

NOTES

1. Soldering operations

1) For manual soldering;

By using 18W Max. (iron tip temperature:

320

°

C

608

°

F

Max.) soldering should be

completed within 3 seconds.

2) For reflow soldering;

Perform soldering reflow at a peak sur-

face temperature of the PC board not to

exceed 245

°

C

473

°

F

. See the below rec-

ommended temperature profile.

3) During soldering, care should be taken

not to apply excessive stress to the termi-

nals as the resulting deformation may

cause malfunction. Excessively high sol-

der tab temperature and soldering iron

wattage should also be avoided as these

factors may harm switching performance.

2. Setting of the operation object

In setting the operation object; keep the

following distance between the switch bot-

tom and the operation object at T.T.P. (To-

tal Travel Position)

ABP811161P: 2.3 to 2.9mm

.091 to .114 inch

ABP811261P: 3.5 to 4.1mm

.138 to .161 inch

3. Quality Check under Actual Loading

Conditions

To assure reliability, check the switch un-

der actual loading conditions. Avoid any

situation that may adversely affect switch-

ing performance.

4. Environment

1) These switches do not have a sealed

construction. As such, the construction of

the equipment in which the switches are

to be installed should be given careful

consideration when the switches are to be

used in locations where corrosive gases,

silicon or other substances which will ad-

versely affect the contacts are used,

where there is a high concentration of

dust or where the switches may be ex-

posed to condensation or water. Using

switches in locations like these may cause

malfunctioning.

2) Avoid using this switch in high-temper-

ature, high-humidity or condensation-

forming environments and avoid allowing

droplets of water to remain on the switch

or come into contact with it. These condi-

tions may interfere with the performance

of the switch (resulting in short-circuiting,

migration, etc.). Use the type with the gold

contacts in applications involving trains,

aircraft, motor vehicles or medical equip-

ment where the switch must satisfy safety

and high reliability requirements. Please

consult with us for the applications re-

quired high reliability.

3) Because the humidity range differs de-

pending on the ambient temperature, the

humidity range indicated below should be

used. Continuous operation of the switch

is possible within this range, but continu-

ous use near the limit of the range should

be avoided.

• This humidity range does not guarantee

permanent performance.

Recommended condition for

reflow temperature profile

T

e

mper

ature (

°

C

°

F

)

Preheating

within 2 min.

with 30 sec.

245

473

220

428

150

302

;;

;;;;

;;;;;;

;;;;;;;;

;;;;;;;;;

;;;;;;;;;;

;;;;;;;;;;

;;;;;;;;;

;;;;;;;

;;;;;

;;

;

;

Temperature,

°

C

°

F

Tolerance range

85

5

0

+32

80

176

–25

–13

(Avoid

condensation

when used at

temperatures

higher than 0

°

C

32

°

F

)

Humidity, %R.H.

(Avoid freezing when

used at temperatures

lower than 0

°

C

32

°

F

)

mm

inch