6

3.2.

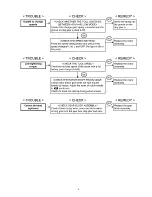

Trial Operation (after checking Troubleshooting Guide).

3.2.1.

Assembly

• Confirm if there is no gap between housing A, B and C by pinching lead wires.

• There is no dust or deformation on battery terminals.

3.2.2.

Operation

• Check whether the tool operates properly in both the forward and reveres directions.

• Press the light button on the operation panel to confirm that the LED lights up.

• Check whether the tool speed increases continuously as the trigger is gradually engaged.

• Rotate the clutch handle and check whether the clutch switches properly.

• Check if the rotation speed is normal rated value.

High: 1580/min (rpm) at 18V, 1350/min (rpm) at 14.4V

Low: 470/min (rpm) at 18V, 400/min (rpm) at 14.4V

• Pull the trigger all the way back and check whether the tool stops rotating immediately when it is released.

• Set the clutch handle to the [

] mark and check whether the tool rotates without any clutch operation.

• Operate (rotate) the keyless chuck and check whether the chuck's three jaws move smoothly.

3.2.3.

Integrity

• With the switch activated, shake the tool back and forth and up and down and verify that its sound does not change excessively.

• Check for the presence of any dirt or foreign matter from the repair process on the outside of the tool.

Содержание EY74A2

Страница 3: ...3 3 Troubleshooting Guide 3 1 Troubleshooting Guide ...

Страница 4: ...4 ...

Страница 5: ...5 ...

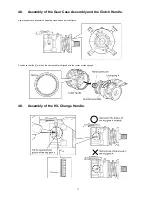

Страница 12: ...12 4 10 Wiring and Assembly Points ...

Страница 13: ...13 5 Wiring Connection Diagram 6 Schematic Diagram ...

Страница 14: ...Model No EY74A2 Exploded View ...