MICRO-IMAGECHECKER

®

A 210

•

A110 MultiChecker V2 Series

MICRO-IMAGECHECKER

®

A 210

•

A110 MultiChecker V2 Series

10

11

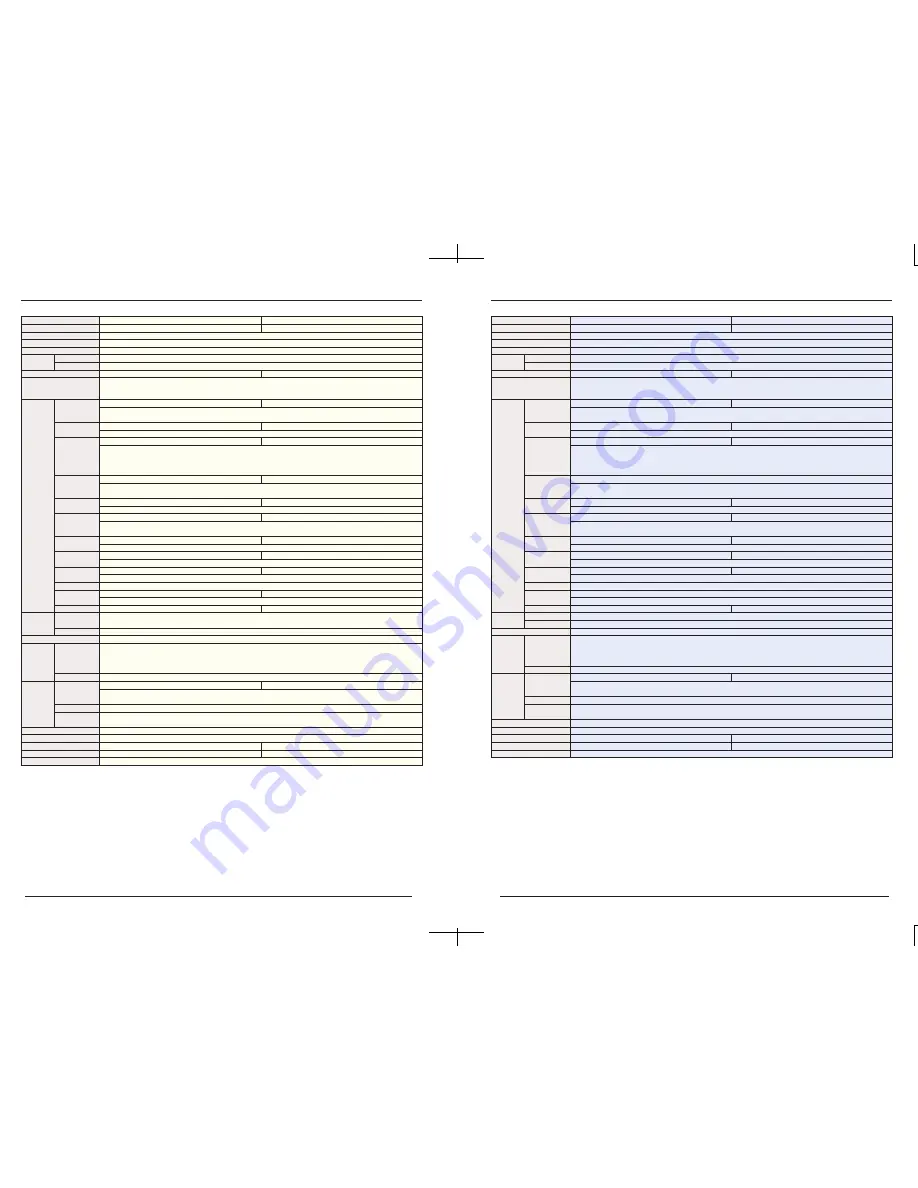

■

A210

•

A110 Multi-checker V2 specifications

A210 Multi-checker V2

A110 Multi-checker V2

64

32

Max. 96 per product type Rotation position adjustment function

Max. 48 per product type X-Y position adjustment function

Smart matching = Max. 96 pcs.; Equipped with post-detection ifferential processing function

Matching = 48 per product type

32-bit RISC CPU (high-speed processing version)

32-bit RISC CPU

512

×

480 (pixels)

×

256 gradations

Max. 96 per product type

Max. 48 per product type

Menu selection using the key emulation function (ver. 2.2 or later).

Max. 96 per product type

Max. 48 per product type

Shape: rectangular/polygonal or oval mask Shape: rectangular/polygonal or oval Gray-scale mean value detection/judgement

Change between gray-scale memory/gray-scale through/binary memory (A/B/C/D/E/F)/binary through (A/B/C/D/E/F)/gray-scale NG/binary NG (A/B/C/D/E/F)

8 bit 256 gradations

6 groups of binary processing from the gray-scale memory (upper and lower threshold settings)

Execute All mode: Execute all set checkers

Automatic Switch mode: Change the checker to be executed in accordance with the judgment output result

User-Defined mode: Specify the checker for execution when the start signal is input

Shape: rectangular Binarization adjusts according to changes in the gray-scale data Gray-scale mean value detection/judgement

Sub-pixel accurate multiple detection matching by gray-scale correlation processing

Rotation by raster detection and raster detection position (±30 degrees)

Output = number of detected items/correlation numbers/position/angle teaching registered

changes can be imported from external source smart teaching (A210) = judgement learning function by the smart template

CPU

Frame memory

Operator interface

Monitor display

Processing

Gray-scale

Exposure

adjustment

Gray-scale window

Smart matching/

matching

(sub-pixel processing)

Gray-scale edge

detection

(sub-pixel processing)

Feature extraction

Binarization

Number of product types

Execution modes

Inspection

Position/

rotation position

adjustment function

Priority adjustment multi-stage adjustment sequence setting by

matching/gray-scale edge/binary edge or feature detection.

Max. 96 per product type

Max. 48 per product type

Scanning method = individual/projection gray-scale filter/width function detection by sub-pixel unit

Detection position = forepoint/forepoint and afterpoint/largest differential/multiple edge

Max. 96 per product type

Max. 48 per product type

Shape = rectangular/polygonal or oval mask Shape = rectangular/polygonal or oval

Image filtering Labeling Output values: counter/center of gravity (to one decimal place)/area/shading/width/principle axis angle

Max. 96 per product type

Max. 48 per product type

Shape = rectangular/polygonal or oval mas Shape = rectangular/polygonal or oval Image filtering White/black pixel number count/judgement

Max. 96 per product type

Max. 48 per product type

Shape = line/mask filter/width functions forepoint edge detection

Max. 96 per product type

Max. 48 per product type

Max. 96 per product type

Max. 48 per product type

External output (D) register = Max. 96 per product type Internal judgement (R) register = Max. 96 per product type External output (D) register = Max. 48 per product type Internal judgement (R) register = Max. 48 per product type

Shape = straight line/polygonal line/circle or arc Image filters White/black pixel number count/judgement

Sine, cos, absolute differential and projection distance functions four data calculations, arctangent, root, the distance-between-points special substitutions reference to previous data output control

RS232C = 2ch (max.115200bps) Compatible with Matsushita Electric Works PLC FP series

Compatible with Mitsubishi MELSEC A Series/FX Series, Omron C Series PLCs, and Allen-Bradley SLC 500 PLCs (Ver. 2.2 or later)

Input = 11points Output = 14 points Removable screw-down terminal block

Image trigger (timing sensor unnecessary) external sensor timing repeat start

Trap function Image storage function

Display item suppressing function (menu display hide function)

Image suppress function when setting checkers, Image rotation function when setting checkers (A210)

Clearly display reject location, Rotational adjustment angle display (A210), Data Monitor function

Display of image processed with image filter, simple spreadsheet, checker list display

30 screens

8 screens

Save/load function for inspection image (all screens/problem screens)

Store images for reinspection/resetting Windows-PC image save/load function

Focus setup, aperture setup, lighting adjustment, image profile monitor, recommended

threshold level, I/O monitor, enforce output

Double-speed random camera (progressive)/flash/electronic shutter used

Image data and setup data can be saved to a Windows PC using vision Backup Tool Ver.

High-speed random trigger camera (progressive) = ANM831 Standard camera = ANM830A, Composite video (NTSC) input used (however the connection requires one port)

24 V DC less than 0.9 A

24 V DC less than 0.7 A

2

1

External

interface

Serial

Judgement output

Parallel

Maximum of 8 graphics/type (line, rectangle or circle), and registered images are displayed on the main screen

Marker function

Inspection start

Other

specifications

Display functions

Setup tools

Image storage

function

Debugging

Setup help

Moving object inspection

Camera support

Number of support cameras

Operating voltage

Setup data backup

*

Binary window

Binary edge detection

Line

Numerical

calculations

Type data saved in the previous controller of the MICRO-IMAGECHECKER A Series (Ver. 1) cannot be directly restored to V2 using the Vision Backup-Tool. In this case, you will

need the dedicated data conversion software (freeware) to convert the Ver. 1 type data for V2 use. If you require the data conversion software or information about how to use it,

contact your Matsushita Automatic Controls Co. Ltd. representative. You can also download the data converter software from the follwing Web page. http://www.naisvision.com/j

Conversion data

4 registers, Can quote to numerical conversion, Can convert numerical conversion result to actual distance, Standard distance, No. of pixels, Cooefficient

■

A210

•

A110 Multi-checker specifications

A210 Multi-checker

A110 Multi-checker

64

32

Max. 32 per product type Rotation position adjustment function

Max. 4 per product type

Smart matching = 32 pcs.; Equipped with post-detection ifferential processing function

Matching = 4 per product type

32-bit RISC CPU (high-speed processing version)

32-bit RISC CPU

512

×

480 (pixels)

×

256 gradations

Max. 8 per product type

Max. 4 per product type

Menu selection by specialized keypad

Max. 32 per product type

Max. 16 per product type

Shape: rectangular/polygonal or oval mask Shape: rectangular/polygonal or oval Gray-scale mean value detection/judgement

Change between gray-scale memory/gray-scale through/binary memory (A/B/C/D)/binary through (A/B/C/D)/gray-scale NG/binary NG (A/B/C/D)

8 bit 256 gradations

4 groups of binary processing from the gray-scale memory (upper and lower threshold settings)

—

Shape: rectangular Binarization adjusts according to changes in the gray-scale data Gray-scale mean value detection/judgement

Sub-pixel accurate multiple detection matching by gray-scale correlation processing

Rotation by raster detection and raster detection position (±30 degrees)

Output = number of detected items/correlation numbers/position/angle teaching registered

changes can be imported from external source smart teaching (A210) = judgement learning function by the smart template

CPU

Frame memory

Operator interface

Monitor display

Processing

Gray-scale

Exposure

adjustment

Gray-scale window

Smart matching/

matching

(sub-pixel processing)

Gray-scale edge

detection

(sub-pixel processing)

Feature extraction

Binarization

Number of product types

Execution modes

Inspection

Position/

rotation position

adjustment function

Priority adjustment multi-stage adjustment sequence setting by

matching/gray-scale edge/binary edge or feature detection.

Max. 32 per product type

Scanning method = individual/projection gray-scale filter/width function detection by sub-pixel unit

Detection position = forepoint/forepoint and afterpoint/largest differential/multiple edge

Max. 32 per product type

Max. 16 per product type

Shape = rectangular/polygonal or oval mask Shape = rectangular/polygonal or oval

Image filtering Labeling Output values: counter/center of gravity (to one decimal place)/area/shading/width/principle axis angle

Max. 32 per product type

Max. 16 per product type

Shape = rectangular/polygonal or oval mas Shape = rectangular/polygonal or oval Image filtering White/black pixel number count/judgement

Max. 64 per product type

Max. 32 per product type

Shape = line/mask filter/width functions forepoint edge detection

Max. 32 per product type

Max. 16 per product type

32 per product type

External output (D) register = Max. 32 per product type Internal judgement (R) register = Max. 32 per product type External output (D) register = Max. 8 per product type Internal judgement (R) register = Max. 8 per product type

Shape = straight line/polygonal line/circle or arc Image filters White/black pixel number count/judgement

4 arithmetic calculations, arctangent, root, the distance-between-points special substitutions reference to previous data output control

Input = 11points Output = 14 points Removable screw-down terminal block

RS232C = 2ch (max.115200bps) Matsushita Electric Works PLC compatible with FP series

Image trigger (timing sensor unnecessary) external sensor timing repeat start

Trap function Image storage function

Display item suppressing function (menu display hide function)

Image suppress function when setting checkers, Image rotation function when setting checkers (A210)

Clearly display reject location, Rotational adjustment angle display (A210)

Numerical calculations results display, Image filtering display function, Accumulated data display, Display list of checkers

32 screens

8 screens

Save/load function for inspection image (all screens/problem screens)

Store images for reinspection/resetting Windows-PC image save/load function

Focus setup, aperture setup, lighting adjustment, image profile monitor, recommended

threshold level, I/O monitor, enforce output

High-speed random trigger camera (progressive)/flash/electronic shutter used

Setup data can be saved to a Windows PC using the Vision Backup-Tool Ver. 2

Double-speed random camera (progressive) = ANM831 Standard camera = ANM830A, Composite video (NTSC) input used (however the connection requires one port)

24 V DC less than 0.9 A

24 V DC less than 0.7 A

2

1

External

interface

Judgement output

Conversion data

Parallel

Serial

—

Marker function

Inspection start

Other

specifications

Display functions

Setup tools

Image storage

function

Debugging

Setup help

Moving object inspection

Camera support

Number of support cameras

Operating voltage

Setup data backup

*

Binary window

Binary edge detection

Line

Numerical

calculations

Type data saved in the previous controller of the MICRO-IMAGECHECKER A Series (Ver. 1) cannot be directly restored to V2 using the Vision Backup-Tool. In this case, you will

need the dedicated data conversion software (freeware) to convert the Ver. 1 type data for V2 use. If you require the data conversion software or information about how to use it,

contact your Matsushita Automatic Controls Co. Ltd. representative.

4 registers, Can quote to numerical conversion, Can convert numerical conversion result to actual distance, Standard distance, No. of pixels, Cooefficient