10

Palmgren Operating Manual & Parts List

84112

MAINTENANCE (CONTINUED)

•

Loosen and remove two socket head bolts. Remove the belt

cover.

•

Remove belt by walking the belt (one groove at a time) from

both pulleys alternately. Pull the belt while turning the pulleys

at the same time.

•

Replace with new belt. Walk the belt onto the pulleys in the

reverse manner as when removing belt.

•

Make sure the belt is evenly seated on all grooves on both pul-

leys.

•

Reinstall dust collection assembly.

•

Replace right side cover and cap. Secure cap with set screws.

Replace return rollers. Replace handle and secure with plug and

socket head bolt. Replace dust chute and secure with socket

head bolt.

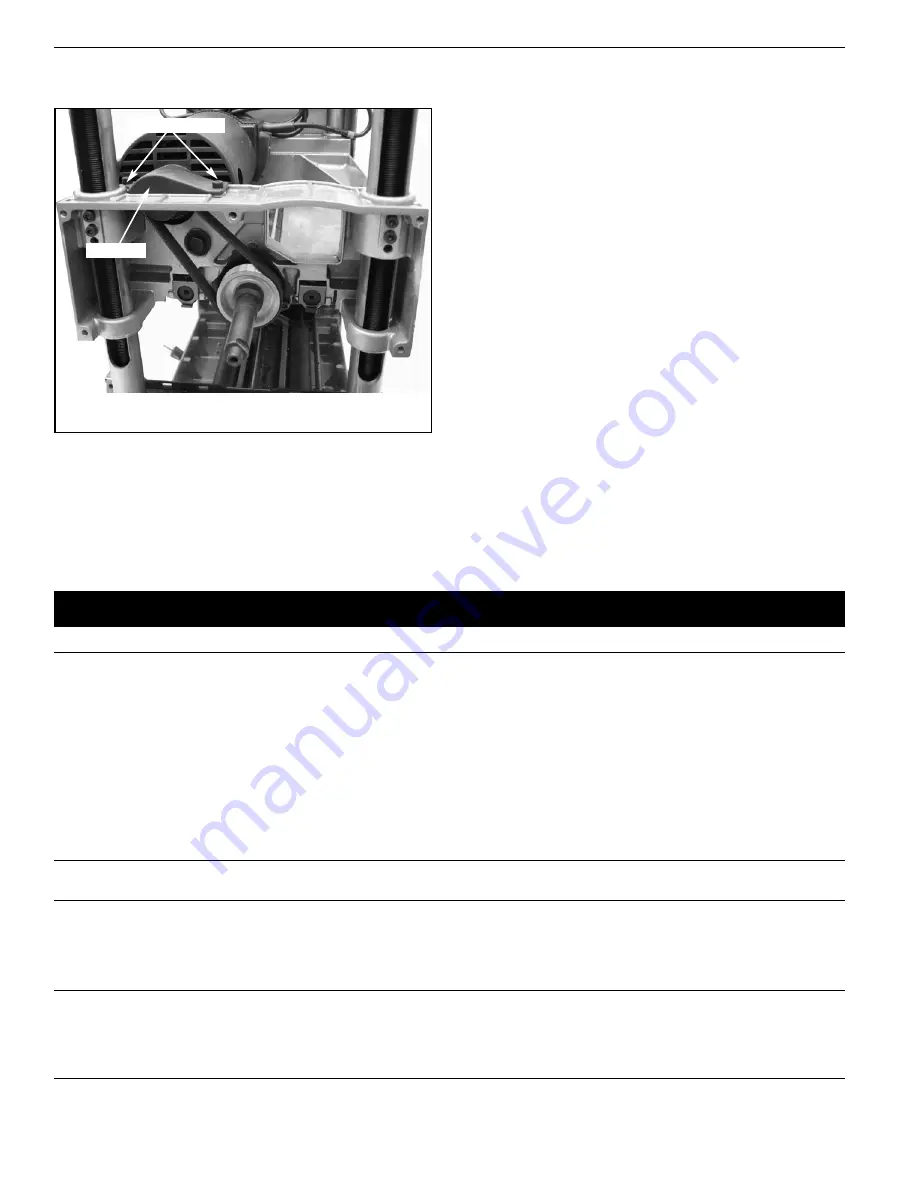

Figure 21 – Right Side of Planer with Side Cover and Dust

Collector Removed

Belt Cover

Socket Head Bolts

T

TR

RO

OU

UB

BL

LE

ES

SH

HO

OO

OT

TIIN

NG

G

SYMPTOM

Snipe

(gouging at ends of board)

Fuzzy grain

Torn grain

Rough raised grain

Uneven depth of cut

(side to side)

POSSIBLE CAUSES

1. Dull blades

2. Inadequate support of long boards

3. Uneven force on cutterhead

4. Rollercase not level with base

5. Lumber not butted properly

Planing wood with a high moisture content

1. Too heavy a cut

2. Blades cutting against grain

3. Dull blades

1. Dull blades

2. Too heavy a cut

3. Moisture content too high

Rollercase not level with planer base

CORRECTIVE ACTION

1. Replace blades per instructions. See

“Maintenance”

2. Support long boards. See “Avoiding Snipe”

3. Gently push board when board is in

contact with only one feed roller.

See “Avoiding Snipe”

4. Adjust rollercase. See “Adjusting Table

Level”

5. Butt end to end each piece of stock as

boards pass through planer

Remove high moisture content from wood

by drying

1. Review “Depth of Cut”

2. Review “Feeding Work”

3. Replace blades per instructions. See

“Maintenance”

1. Replace blades per instructions. See

“Maintenance”

2. Review “Depth of Cut”

3. Dry the wood or use dried wood

Rollercase not level. See “Adjusting Table

Level”