www.pall.com/biopharm

37

5.

Post-use Treatment of Cassettes and System

Once the TFF Process has been completed and the product recovered, the Omega membrane

cassettes can be cleaned and reused. There are several steps that must be followed to remove

remaining contaminants and return the cassettes to initial condition.

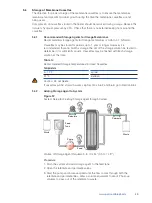

Figure 26

Sequence of Steps for Post-use Treatment of TFF Cassettes

The cleaning process should also be documented and validated if cassettes will be reused in production

of a biopharmaceutical product. This flushing and cleaning process takes considerable time and uses

substantial quantities of water and cleaning agent. It may be worth evaluating the economics of cleaning

and validation for reuse compared to discarding cassettes after a single use.

5.1

Flushing Cassettes after Use

Following a TFF process, the product, if in the concentrate, would have likely been recovered

by displacement with buffer followed by a recirculation and flushing with a small additional

volume of buffer. In this case, it may not be necessary to flush the cassette before adding

cleaning solution.

If the product was in the permeate, the concentrate should be flushed from the cassette using

water or buffer prior to introducing cleaning solution.

5.1.1

Flush the Feed/Retentate Line to Waste

Volume Required:

10 L/m

2

(1.0 L/ft

2

)

Direct the retentate and permeate lines to waste.

Figure 27

System Setup for Flushing to Waste

Step

5

Buffer

Condition

4

Determine NWP and

Membrane Recovery

3

WFI Flush

2

Clean-in-

Place

1

Buffer or

WFI Flush

Optimization or

Processing Mode

Retentate

Permeate

Feed

Tank

Waste

Waste

Feed

Pump

Pp

Rp

Fp