www.pall.com/biopharm

35

4.7

Buffer Conditioning

Buffer conditioning the membrane cassettes and TFF assembly is critical for most

biopharmaceutical applications.

Buffer conditioning removes trapped air from the membrane cassette and system and

establishes conditions for pH, ionic strength and temperature to match the process sample.

This is important to prevent sample precipitation or denaturation when it is first introduced into

the system.

For this operation, use the same buffer that was used to prepare the sample.

The buffer must be at the same temperature as the process fluid.

Membrane cassettes and hardware that are subject to substantial temperature changes

(> 10 °C) will require a torque adjustment to be made on the cassette holder after steady state

is reached. For example, if the hardware surface temperature is 20 to 25 °C and fluid is

introduced at 4 °C, the torque on a full stack of cassettes may drop 20 to 40% due to

contraction of the polymeric elements. In such cases, integrity testing should be performed

after all adjustments have been made.

Volume of Buffer Required: 5 to 20 L/m

2

(0.5 to 2 L/ft

2

). (Less buffer may be required for large

process systems.)

4.7.1

Flush the Retentate and Permeate Lines with Buffer

Direct the retentate and permeate lines to waste.

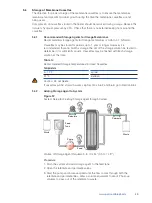

Figure 24

Setup for Buffer Conditioning — Initial Flush

Procedure

1. Drain the system and feed tank, then fill feed tank with buffer.

2. Open the permeate and retentate valves.

3. Start the pump and increase pump speed until liquid begins to flow through both

the retentate and permeate lines. If necessary, adjust the retentate valve to force

flow through permeate.

4. Run for 5 to 10 seconds, then stop.

Retentate

Permeate

Feed

Tank

Waste

Waste

Feed

Pump

Pp

Rp

Fp