24

6.5.1Method of adjusting motor brake gap <PEH100-1/200-2/200-1/300-2/500-2>

Time to adjust

1 When the brake function affects the operation of hoist

2 Brake lining motion causes abnormal noise

3 Brake gap is over 0.7mm.

※Note:To prevent risks , the hoist must be in unload and power-off during the

adjustment

Tools needed

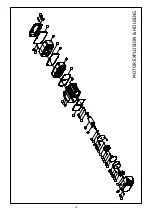

Figure

A. Hex Wrench

B. Thickness gauge

A

B

Method of adjusting

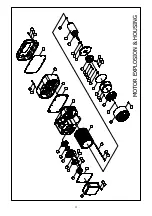

Figure

1. Use hex wrench to loosen ○

1 set screw,

then ○

2 Y type shim can be adjusted.

2. The thicknesses of Y type shim are 0.2mm

and 0.3mm. Adjust quantity as needed.

3. After adjusting each set screw of Y type

shim, Tighten the set screws evenly.

4. Use thickness gauge to check gap.

At least 3 – 4 measuring points. Gap

about 0.2~0.35mm.

5. Make sure all measuring points reach gap

value :

0.3~0.4mm. Then tighten the ○

1

set screw.

6. Check the gap again. If there is an error,

re-adjust again.