33

8.

Rotate the crank to the next top dead centre position

and repeat the procedure for each piston. Turn crank

360 degrees to check correct functioning.

9.

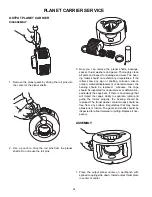

Fit the gasket (28) to the output flange (24 A / B). Turn

the motor 180 degrees to allow valve to be fitted.

10. Lubricate valve (2) and Inside Bore of Housing (3).

11. Rebuild the valve assembly in the reverse order.

Check it rotates freely. Fit valve assembly on to the

motor ensuring the different size drive dowels (61)

and (62) are located in the crankshaft.

The remaining build procedure is the reverse to initially

dismantling.

SPX FLUID POWER

RM Air Motor

Installation / Maintenance / Servicing

Содержание BRADEN BA5A

Страница 2: ......

Страница 25: ...23 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 26: ...24 WINCH CROSS SECTION...