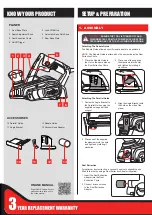

The planer has a precision machined ‘V’ groove in the Front Base

Plate for making 45

o

chamfers along the edges of your workpiece.

PLR-750

4. PLANING

5. REBATE CUTS

2 Place the groove

precisely on the corner

of the workpiece.

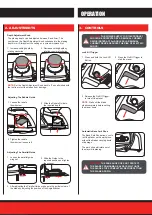

1 Set the required depth on the

planer.

NOTE:

A layer of material will

be removed from the workpiece

even if the cutting depth is set

to 0; always test the setting on a

scrap workpiece first.

1 Set the required depth on the

planer.

NOTE:

For finishing surfaces,

use a low chip depth and

make multiple passes over the

material.

2 Switch on the planer.

3 Lower the planer onto the

workpiece, and push the planer

over the surface with both hands.

NOTE:

Ensure that both base plates

lie flat along the material during

planing.

NOTE:

Ensure the operating

pressure is applied to the rear base

plate when lifting the planer off the

material.

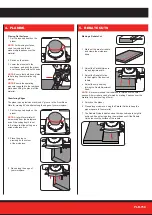

5 Switch on the planer.

6 Plane along workpiece, using the Parallel Guide to keep the

planer square to the material.

7 The Rebate Guide indicates when the required rebate height is

achieved. Keep planing along the workpiece until the Rebate

Guide touches the surface of the rebate.

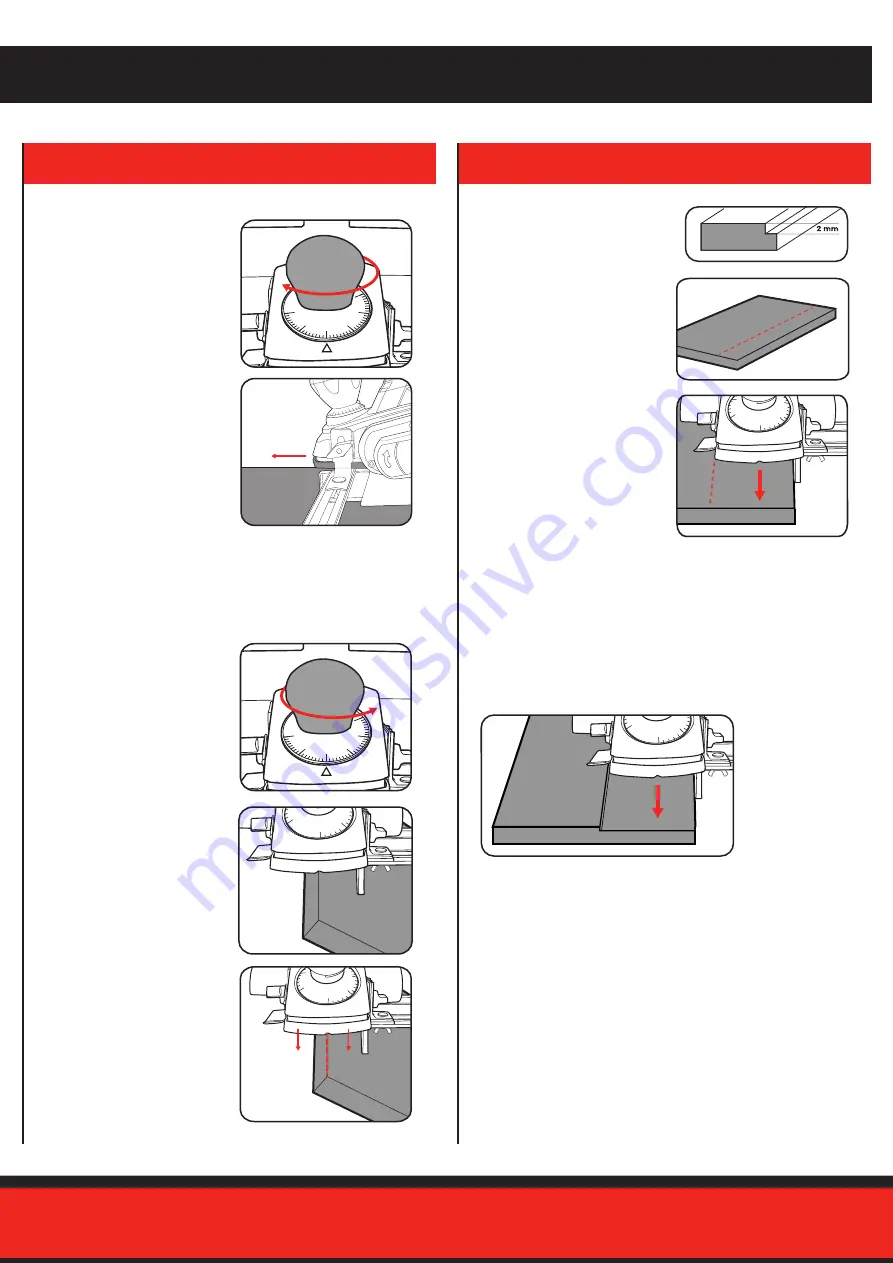

2 Adjust the Parallel Guide to

the appropriate width.

3 Adjust the Rebate Guide

to the height of the desired

rebate.

4 Adjust the chip depth by

turning the Depth Adjustment

Knob.

NOTE:

It is recommended that rebates are formed over several

passes. A 6mm rebate can be formed by making 3 passes over the

material at a depth setting of 2mm.

1 Mark out the area for rebate

and clamp the workpiece

down.

1

1

2

Chamfering Edges

Making a Rebate Cut

Planing Flat Surfaces

3 Plane along the edge of

your workpiece.