SPECIFICATIONS - MODEL NO. MSH-115

10

6. Position the two pieces of metal you wish to join.

7. Hold the electrode approximately 2 cm away from the desired join area. Lower

or hold the welding mask over your face. Lower the electrode slowly and

proceed to strike the electrode tip against the desired join area on the work

piece as if you are striking a match. This is the correct strike up method.

Note:

Hitting the electrode on the work piece can damage the electrode flux

coating and make strike up difficult.

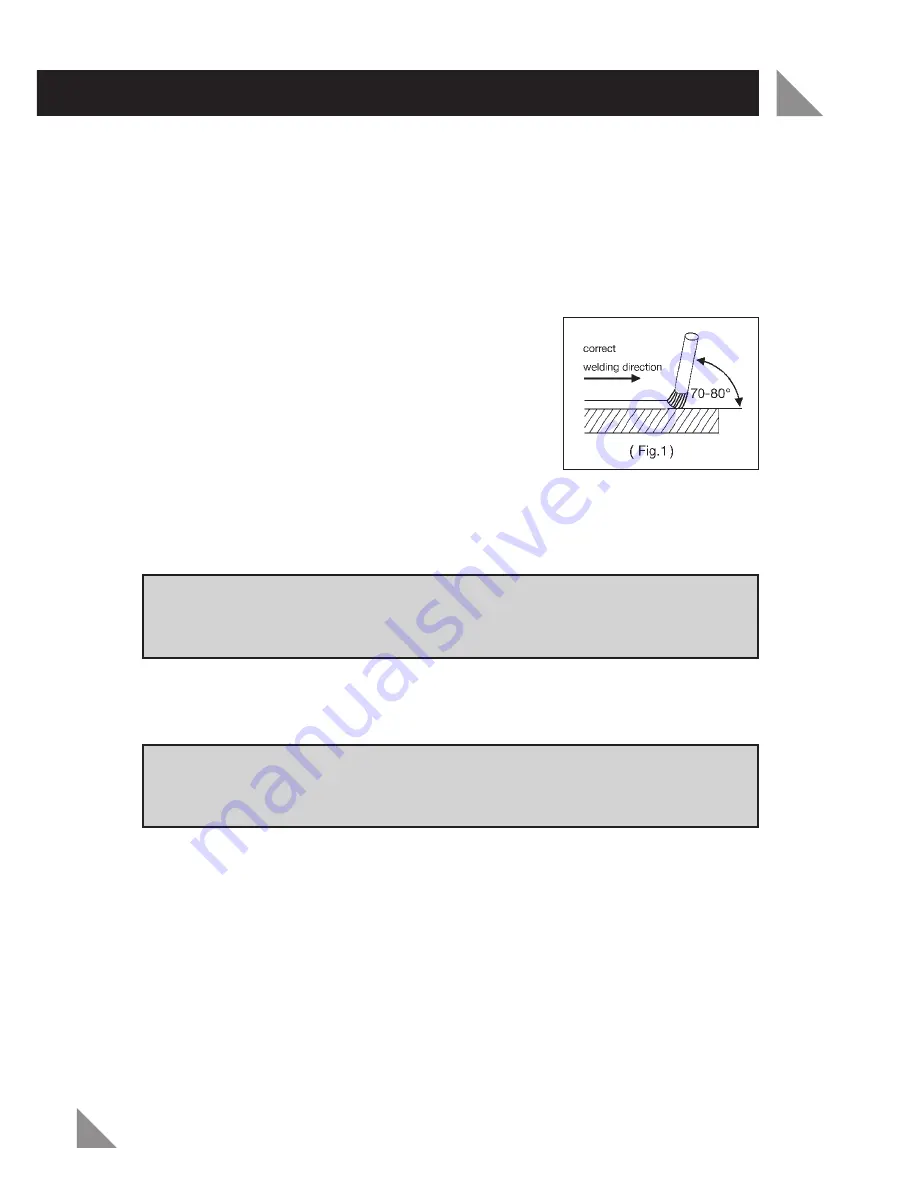

8. The end of the electrode should ignite. The

ignition of electrode end is called the “arc”. As

soon as you have the arc, try to maintain a distance

from the work piece equal to the diameter of the

electrode being used. Weld along your desired

join from left to right. Try to keep this distance

consistent for the duration of the weld. The angle

of the electrode as it is advanced should be

between 70 to 80˚ to the welding direction (Fig. 1). When you have reached

the end of the weld bead bring the end of the electrode backwards and quickly

lift the electrode from the weld. By removing the electrode from the metal you

have broken the electrical path and the arc will extinguish.

Warning!

Failure to use a welding mask can result in “eye flashing” where your

naked eye sees the arc. Eye flashing is harmful and can damage your eyes.

Always look through the tinted glass of the welding mask when observing the arc.

The welding mask protects your face from the welding sprays and ultra violet rays

produced by the arc. The tinted glass is essential for protecting your eyes while

observing the arc.

Warning!

During and immediately after welding the weld will be extremely

hot. Ensure it has cooled before touching with your hands. If it needs to be

moved while still hot use a clamping device.

9. Once the weld has been completed turn the welders on/off switch to the “Off”

position and disconnect the welder from the power supply.

10. Slag is refuse left around the weld after welding, this should only be removed

after the weld has cooled down and is no longer glowing. To remove this slag

use the combination wire brush and chipping hammer (9) provided in the kit.

Use the chipping hammer (9) side of the wire brush and strike or chip off the

slag from the weld just performed. The slag will chip or break away from your

weld producing a clean looking weld. Use the wire Brush (9) to finish cleaning

up the weld and workpiece ready for a protective coating or paint.