Maintenance operations

11

4. Checking turnstile units

4.1. Clean turnstile parts from contaminants.

4.2. Check if all the cables are properly connected.

4.3. Check and tighten if necessary thread connections that fasten

turnstile units.

5. Lubricating moving parts of turnstile mechanisms

To get an access to the assemblies, for lubrication of the moving parts of

turnstile mechanisms it is required to:

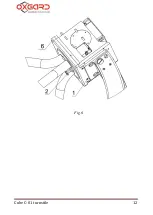

1. Remove lower decorative board having undone two screws 1

(Fig.6)

2. Remove arms unit - to get this:

2.1. Unscrew fixation lock 2 with box spanner D22

2.2. Loose a screw М8, which is in the hole where the fixation lock

was secured with hexagonal key S6.

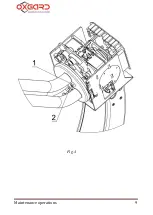

2.3. Loose two screws 1 (Fig.4) М8 with hexagonal key S6

2.4. Remove arms unit.

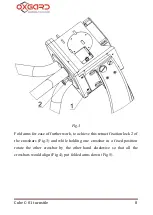

Lubricate the details of the turnstile mechanism (Fig.7) indicated with

numbers 1, 2, 3 and 4.

Lubricating is performed by engine oil of viscosity grade 5W-20 at a rate

of 2 - 3 drops in each slide assembly.

Содержание Cube C-01

Страница 1: ...Maintenance operations www oxgard com info oxgard com Tel 7 812 366 15 94 Cube 01 turnstile...

Страница 2: ......

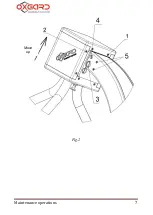

Страница 7: ...Maintenance operations 7 Fig 2 Move up...

Страница 9: ...Maintenance operations 9 Fig 4...

Страница 10: ...Cube 01 turnstile 10 Fig 5...

Страница 12: ...Cube 01 turnstile 12 Fig 6...

Страница 13: ...Maintenance operations 13 Fig 7...

Страница 15: ...Maintenance operations 15...