H

B

A

J

C*

Jamb

10“

Steel

Wood

Concrete/

Masonry

10“

10“

10“

10“

E

Drill

Size

4“

3/8“ exp. anchor

Use ANSI B95.12

carbide tipped

drill bit

3/8“*

3/8“ bolt

3/8“ Lag

4“

4“

4“

4“

D*

Doors

10“

All

All

7/16“

5/16“

Table 1 - Headplate Fasteners

All

10“

10“

10“

10“

F**

Fastener

Specifications

4“

6“

4“

8“

6“

Operation

Operator

Fastener

Push Up

790

790

780

780

Reduced

Chain Drive

Door Type

G

8“

10“

8“

12“

10“

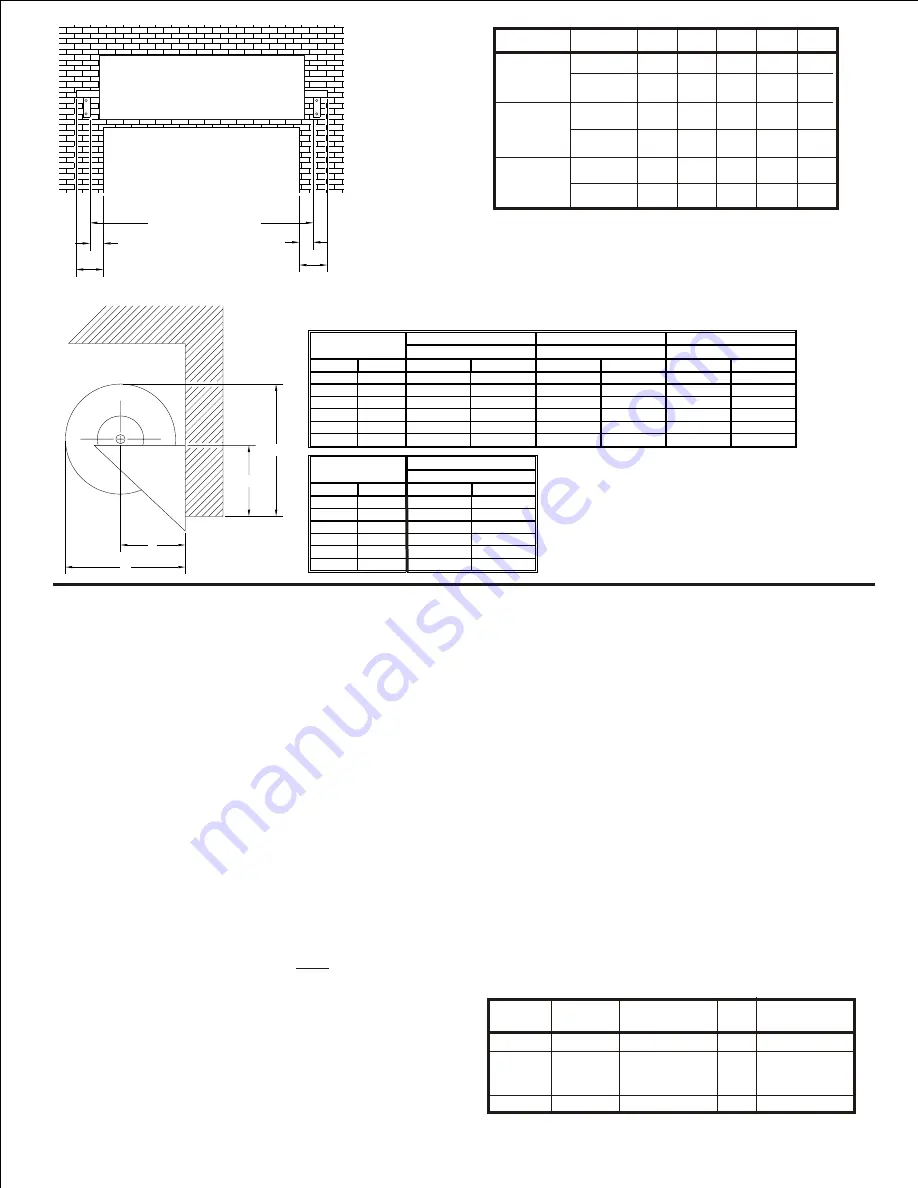

Figure 1

*Excess shaft may be cut off of non-drive sides of

doors for additional clearance. It is recommended that

at least 1” of shaft be retained past the headplate to

facilitate spring tension adjustment.

**Dimension “F” applies to Drive End only.

RH shown, LH opposite.

*Drill size for supplied fasteners. For others, refer to

manufacturer’s specified installation method.

790

780

10“

10“

6“

6“

12“

light weight building jambs from twisting.

Bracing may be required to prevent

NOTES

INSTALLATION

5” above top of guide, if headroom allows)

E, H and G (Figure 1).

1. Locate headplates per dimensions F, (or approximately

2. Hold headplates in mounting position. Using a water

3.

IF DOOR IS CHAIN DRIVEN:

top hole in headplates.

Fasten headplates to wall using three fasteners. Use

the wall. If this condition exists then use Thru-bolt.

unit (CMU) wall.

DO NOT

install fastener in a void in

for brick or stone walls or hollow concrete masonry

Mark mounting hole locations on header. See Table 1

for supplied fasteners.Thru-bolts are recommended

level, check to make sure tops of headplates are level.

OPENING WIDTH + G

E

C

D

F

FOR REFERENCE

DRIVE END

3

a. Remove hardware from package.

b. Slide 1/2“-13 nut and 3/8” external tooth locking

washer over bolt as shown in Figure 2. (Note:

Sharp edges of locking washer must be in contact

with flange of self clinching nut).

c. Thread self clinching nut onto threads of bolt and

snug until finger tight.

d. Insert assembly into one of the 3 outer mounting

holes on end ring.

e. Use a backup wrench(channel lock, vise grips or

equivalent) to prevent 1/2“ nut from spinning while

torquing bolt to seat self clinching nut.

f. While maintaining pressure to keep assembly

seated against ring, use a 9/16“ ratchet, wrench

or power driver to turn the bolt and secure the self

clinching nut.

g. Tighten bolt until self clinching nut is fully seated.

(Resistance against the back up wrench will be felt

as clinching nut begins to seat).

h. With backup wrench still applied to 1/2“ nut,

reverse torque on bolt to remove.

I. Repeat for 2 remaining holes.

j. Place bearing into recess of bracket. (Figure 2)

k. Bolt sprocket to bracket to capture bearing.

l. Slide bracket assembly over shaft, and align

appropriate legs to self clinching nuts in ring.

m. Bolt to ring as shown.

n. Thread hand chain thru chain guide slots, over

chain wheel and connect ends. NOTE: Make sure

chain is not twisted.

o. Slide chain hoist assembly onto door shaft.

p. Install drive chain to sprocket and hoist assembly.

Align both sprockets and tighten set screw on

hoist.

q. Install chain keeper to wall.

See Page 4 For Ilustration

Over

Up To

-

7' 8"

7' 9"

9' 4"

9' 5"

11' 0"

11' 1"

12' 8"

12' 9"

14' 3"

14' 4"

16' 0"

Opening Height

Recommended

Minimum

20 1/4"

18 1/4"

21"

19"

21 3/4"

20 3/4"

22 3/4"

21 3/4"

23 1/4"

22 1/4"

24 3/4"

23 3/4"

B

Head Room

Over

Up To

Recommended

Minimum

Recommended

Minimum

Recommended

Minimum

-

7' 8"

10"

8"

9 1/8"

Same

18 1/8"

Same

7' 9"

9' 4"

10 1/2"

8 1/2"

9 1/8"

Same

18 3/8"

Same

9' 5"

11' 0"

11"

10"

10 1/4"

Same

19 3/4"

Same

11' 1"

12' 8"

11 1/2"

10 1/2"

10 1/4"

Same

20 1/4"

Same

12' 9"

14' 3"

12"

11"

10 1/2"

Same

20 1/2"

Same

14' 4"

16' 0"

13"

12"

10 1/2"

Same

21"

Same

Opening Height

H

J

A

Head Plate Height

Axle Setting

Back Room