―E30―

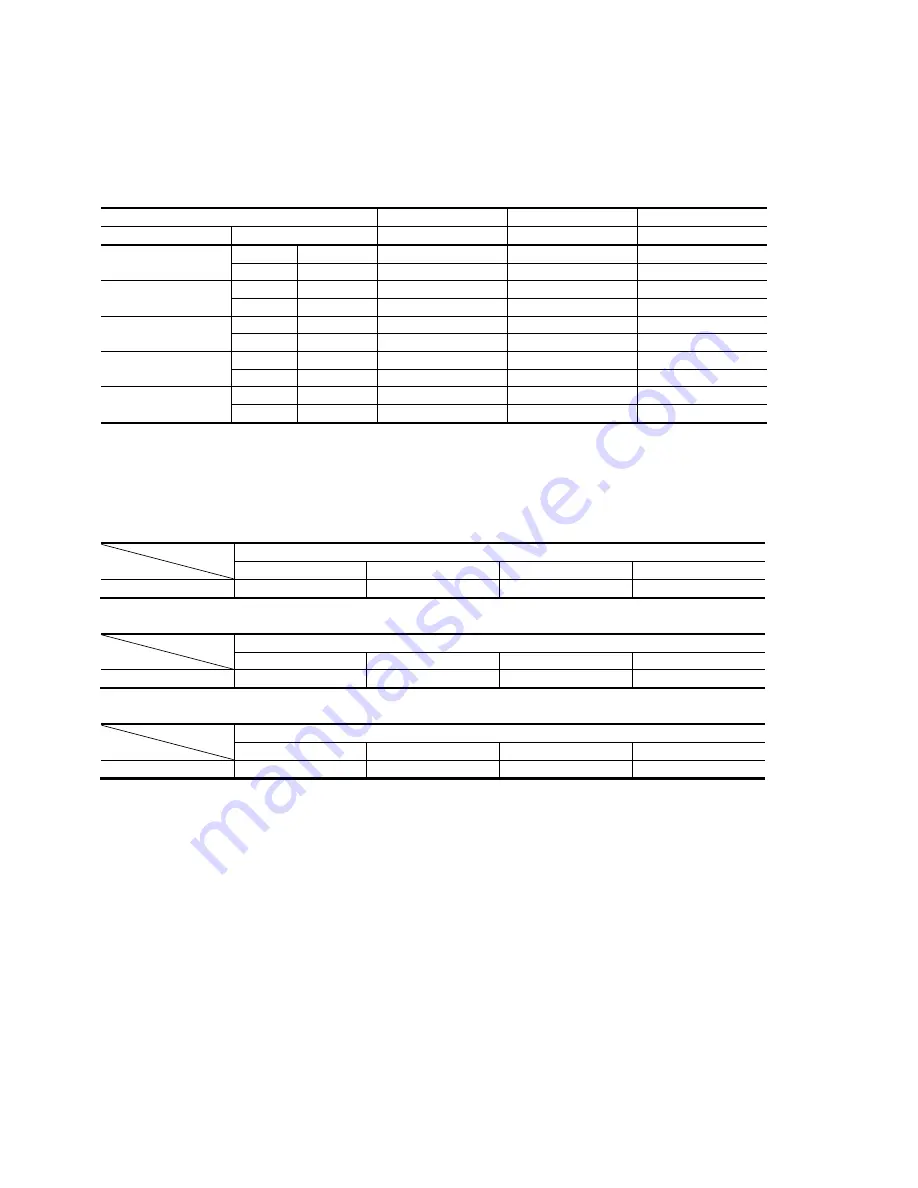

9. PARTS LIST (continued)

9.5 Optional Accessory

(1) Extension cable/hose

Power cable

Applicable current (Rated current)

200 A

350 A

500 A

Cable length

Cable termination

Model

Model

Model

2m

CSRT

CSRT

BKPT-3802

BKPT-6002

BKPT-8002

CSRT

Connector

BKPDT-3802

BKPDT-6002

-

7m

CSRT

CSRT

BKPT-3807

BKPT-6007

BKPT-8007

CSRT

Connector

BKPDT-3807

BKPDT-6007

-

12m

CSRT

CSRT

BKPT-3812

BKPT-6012

BKPT-8012

CSRT

Connector

BKPDT-3812

BKPDT-6012

-

17m

CSRT

CSRT

BKPT-3817

BKPT-6017*

BKPT-8017

CSRT

Connector

BKPDT-3817

BKPDT-6017*

-

22m

CSRT

CSRT

BKPT-3822

BKPT-6022*

BKPT-8022

CSRT

Connector

BKPDT-3822

BKPDT-6022*

-

CSRT (Crimp Style Ring Terminal)

*

When performing pulse welding using the welding power source with 350 A applicable current and a

17m or more cable, use the thicker cable by one rank. (BKPT-80XX, BKPDT-80XX)

Example:

When using a 22 m cable (crimp style ring terminal – DINSE connector)---BKPDT-8022

Control cable (10P)

Cable length

5m

10m

15m

20m

Model

BKCPJ-1005

BKCPJ-1010

BKCPJ-1015

BKCPJ-1020

Gas hose

Hose length

5m

10m

15m

20m

Model

BKGG-0605

BKGG-0610

BKGG-0615

BKGG-0620

Water hose

Cable length

5m

10m

15m

20m

Model

BKWR-0605

BKWR-0610

BKWR-0615

BKWR-0620