No. U5260

P. 10 / 27

6. CONNECTION PROCEDURE

CAUTION

Follow the instructions below to avoid electric shock.

∗

Do not touch the charging parts, as this will result in fatal shock and severe burns.

●

Do not touch the charging parts of the welding machine.

●

Have a qualified electric engineer ground the case of the welding power source and the base

metal or jig electrically connected, following a local low.

●

Disconnect the wire feeder from the welding power source by turning off the line disconnect

switch in the power box to avoid an electric shock before grounding the welding power source

or base metal and connecting the cables or hoses.

●

Do not use a cable with lack of capacity or a cable seriously damaged.

●

Tighten and insulate the connections of cables.

●

Firmly attach the cover of the welding machine after connection of the cables.

●

Do not place the welding power source, wire feeder, torch, and control cable (including the

extension cable) in an area where the equipment can become wet.

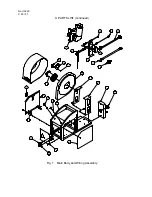

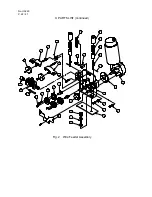

6.1 Connecting to the Welding Power Source and to the Gas Flow Rate Regulator

Standard Composition

NOTE:

Standard composition consists of the parts indicated in

.

Preparation of the parts except the standard composition is required to use the wire feeder.

*Available in 5 m, 10 m, 15 m, and 20 m.

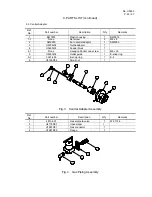

Follow the steps below to connect to the welding power source and to the gas flow rate regulator.

1. Ground the base metal (if required by local laws or codes).

2. Connect between the negative output terminal of the welding power source and the base metal with the base

metal cable.

3. Attach the torch cable to the positive output terminal of the welding power source.

4. Connect the other side of torch cable to the terminal on the back side of the wire feeder.

5. Plug the control cable for the wire feeder (10P) into the wire feeder socket on the welding power source.

6. Attach the gas hose to the gas supply inlet on the wire feeder.

7

.

Connect the water hose (supply water) to the water connection (supply water) of the back of wire feeder and the

water connection (supply water) in front of the water cooler.

Welding

power source

Wire feeder

Base metal cable*

Welding torch

Remote control

cable

Gas

Gas cylinder

Remote control

(Optional)

Firmly attach the DINSE connectors

by turning the connectors in the

clockwise direction.

Gas flow rate regulator

Control cable

Torch cable

Water hose*

(supply water)

Water hose*

(condensed water)

Water cooler

In case of the air cooled

torch is used, water cooler

is not necessary.