Optical Scientific Inc

OFS 2000CW User’s Guide

P/N 1910-905

Rev. 03/28/13

57

11.2 Control Enclosure Troubleshooting

There are no user-serviceable parts in the Control enclosure. Information provided herein may be helpful when

contacting OSI Technical Support.

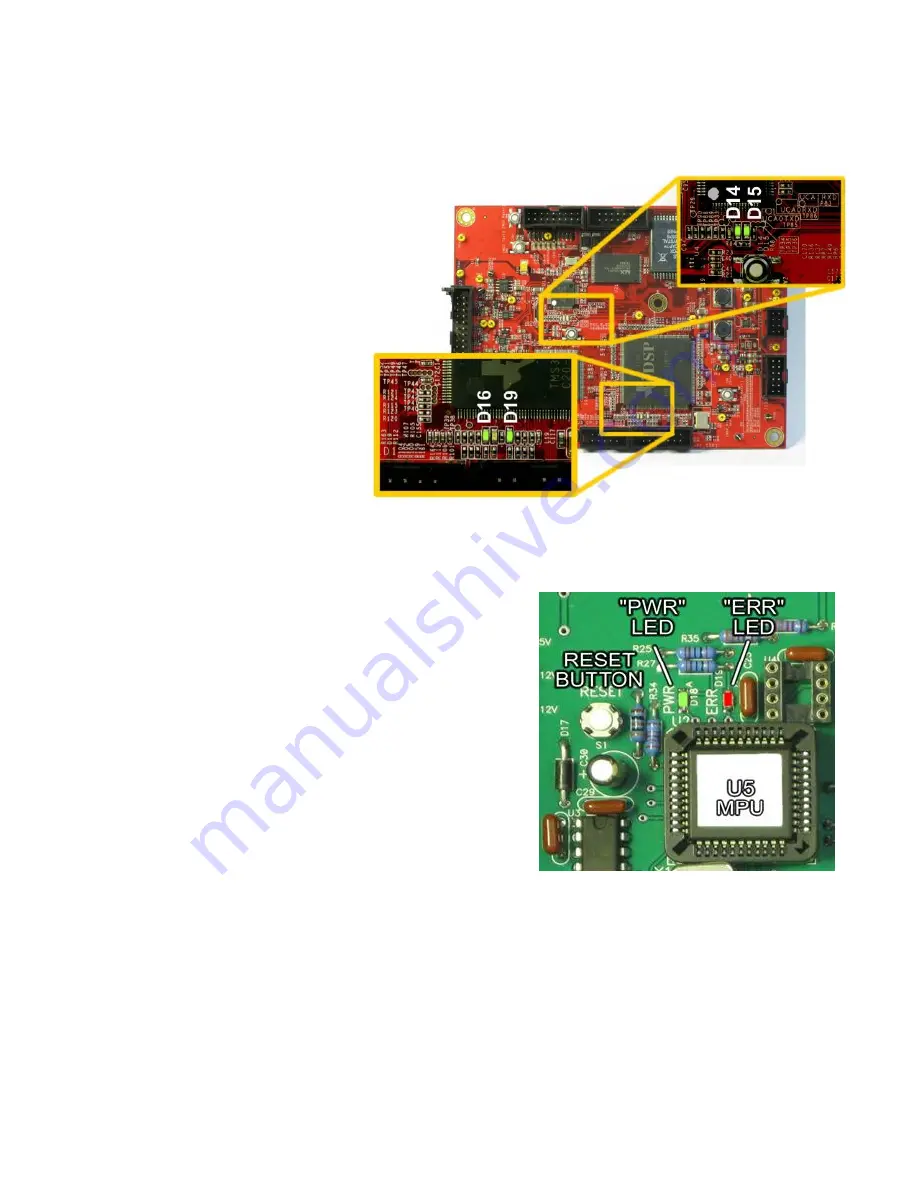

The Control/Interface Board and

DSP (Digital Signal Processing)

board have indicator LED’s which

will show PCB activity and may

help in isolating faults

11.2.1 DSP lndicator LEDs

A quick look at the 4 indicating

LEDs will show any problems.

D14 lit and pulsing [LED0]

D15 lit and steady [LED1]

D16 lit and steady [GP12]

D19 lit and steady [GP15]

If any of the LED's aren't lit, check

the power outputs at the system

DC power supply. If the power

supply voltages are good, check

that all the cables are firmly

seated.

11.2.2 Control/Interface

Indicators

If the system “freezes” or “locks up” or will not respond to the

“V” or “R” poll characters, check the “PWR” (Power) and

“ERR” (Error) LEDs on the Control/Interface Board.

If the PWR LED is not lit, check the AC Line Voltage and the

DC power supply output

voltages. If the “ERR” LED is lit,

press and hold the nearby “RESET” button.

11.3 Transmitter Troubleshooting

11.3.1 Transmitter "Power" Led Not Lit

Check the AC voltage at the transmitter PCB terminal block. If

there is AC voltage present. replace the transmitter board. If

there is no AC voltage present, check the AC supply line for

fault.

11.3.2 Transmitter "Signal" Led Not Lit

Be sure the transmitter module wiring is firmly connected.

Replace the transmitter module.

Replace the transmitter PCB.

11.4 Receiver Troubleshooting

11.4.1 Receiver "Power" Led Not Lit

Check the +/- 8VDC voltages at the receiver PCB terminal block. If there is voltage present. Replace the

receiver PCB. If there is no DC voltage present, check the DC supply line for fault.

Figure 11.1 DSP Indicators

Figure 11.2 Control/Interface LEDs

Содержание OFS 2000C

Страница 9: ...Optical Scientific Inc OFS 2000CW User s Guide P N 1910 905 Rev 03 28 13 2...

Страница 56: ...Optical Scientific Inc OFS 2000CW User s Guide P N 1910 905 Rev 03 28 13 49...

Страница 70: ...Optical Scientific Inc OFS 2000CW User s Guide P N 1910 905 Rev 03 28 13 63 This page intentionally left blank...