Operating instructions EUROTRONIK-20 Page: 3

Mounting

The controller must be mounted in accordance with its system of protection so that it is protected against

moisture. The ambient temperature should lie between 0° C and + 40° C and should be as constant as

possible. The relative humidity should not exceed 95% and no condensation should occur. Direct

incidence of heat or sunlight on the device must be avoided.

The power supply to the device must be connected via an all-polar main switch with a contact gap width of

at least 3mm.

The device must be switched off before the housing is opened.

Preparation of the 6-way valve

Before mounting the EUROTRONIK it must be ensured that the

valve moves easily and is free of dirt.

The 6-way valve must be in the position Filter when mounting

the controller.

In this position the handle of the valve must be

removed by driving the fastening pin out of the valve shaft. Then

insert the shorter osf pin delivered with the device in the middle of

the hole in the valve shaft. If the pin is too loose in the hole, it can

be fastened with a little adhesive or grease to facilitate mounting of

the controller. For later operation of the system it is immaterial

whether the pin is loose because it is centred by the housing of the

controller.

Preparation of the controller

The controller must be in the position

Filter

(position on delivery).

To equalise height differences of the valve shafts, it is necessary in the case of some valves to stick one

or more of the self-adhesive spacer disks delivered with the device under the housing of the controller.

Proceed as follows to determine whether one or more spacer disks are needed:

Move the 6-way valve into the position

Filter

.

Mount the EUROTRONIK-10 on the valve without spacer disk.

See "Mounting of the EUROTRONIK".

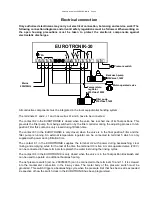

Push the feeler gauge delivered with the device between the

EUROTRONIK and valve.

If the feeler gauge fits between the EUROTRONIK and valve

exactly, the gap is optimal.

If the EUROTRONIK wobbles on the valve, one or more spacer

disks must be stuck under the EUROTRONIK (see sketch below).

Thereafter the EUROTRONIK must be mounted again and the

test with the feeler gauge repeated.

After mounting the feeler gauge has to be removed. The resultant

play has no negative influence on the operation of the system.

Insert

feeler

gauge

Shorter osf-pin

Guide groove

Содержание 3104811211

Страница 14: ......