6

•

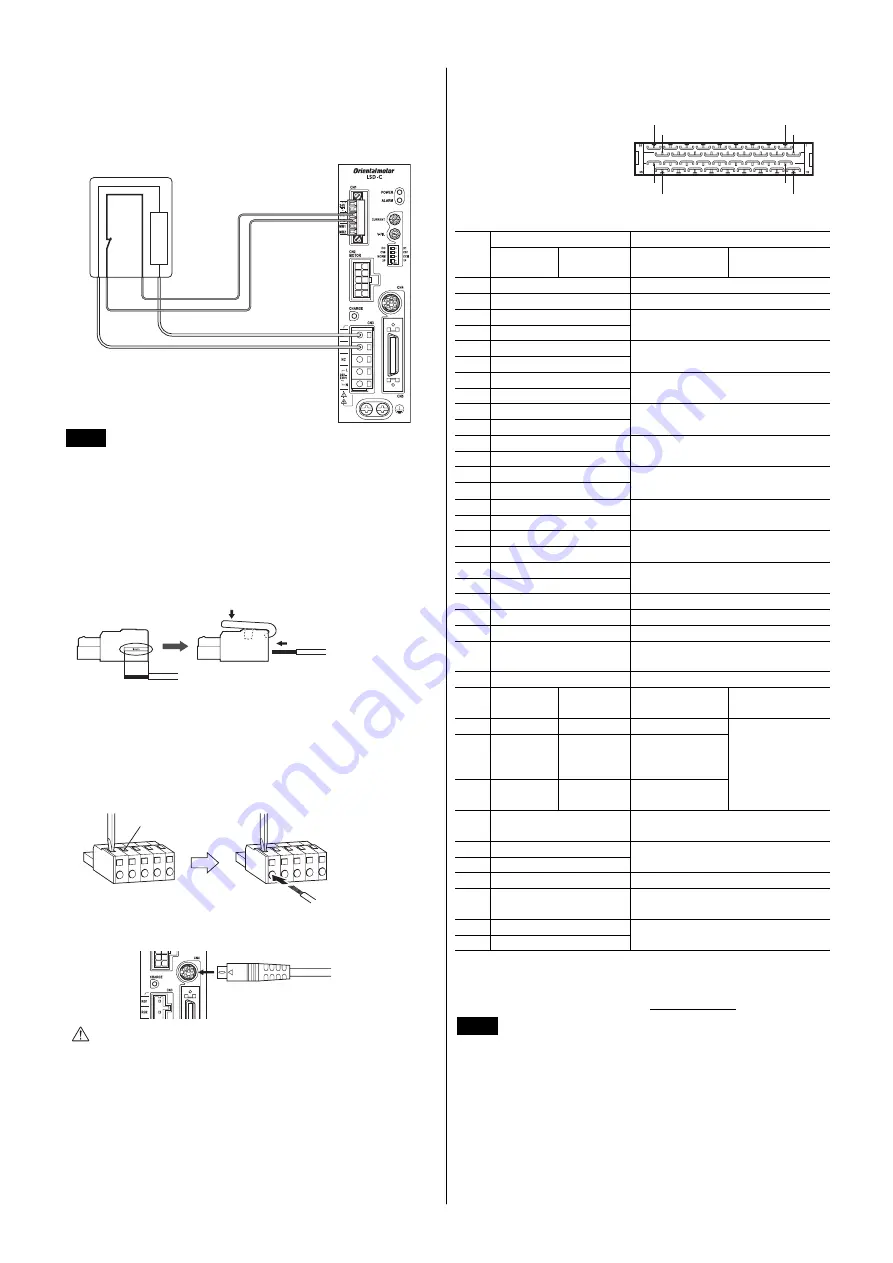

Connecting the regeneration unit

If vertical drive (gravitational operation) such as elevator

applications is performed or if sudden start-stop operation of a large

inertial load is repeated frequently, connect the regeneration unit

RGB100

.

AWG22

AWG18

R

䋺

150

Ω

To RG1 and RG2

terminals on CN3

To TH1 and TH2

terminals on CN1

Regeneration

unit

RGB100

150 °C (302 °F)

[N.C.]

Note

•

Before connecting the regeneration unit, be sure to

remove the jumper wire from the CN1 connector.

•

If the current consumption of the regeneration unit

exceeds the allowable level, the thermostat will be

triggered and a regeneration unit overheat alarm will

generate. If a regeneration unit overheat alarm

generates, turn off the power and check the content

of the error.

CN3

2. Push the connector wiring lever

in the direction of the arrow.

3. Insert the cable.

1. Strip off the cable sheath

based on the strip gauge.

You can also connect the power supply cable using a flat-tip

screwdriver.

Insert a flat-tip screwdriver with a tip of 3.0 to 3.5 mm (0.12 to 0.14

in.) in width into the insertion port and push. In this condition, insert

the cable.

Screwdriver insertion port

Insert the cable while

pushing down the screwdriver.

CN4

OPX-2A

㩷㪺㪸㪹㫃㪼㩷㫆㫉㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅

㪺㪸㪹㫃㪼㩷㪽㫆㫉㩷㪻㪸㫋㪸㩷㫊㪼㫋㫋㫀㫅㪾㩷㫊㫆㪽㫋㫎㪸㫉㪼

Caution

The data edit connector (CN4) and I/O signals

connector (CN5) are not insulated. When

grounding the positive terminal of the power

supply, do not connect any equipment (PC, etc.)

whose negative terminal is grounded. Doing so

may cause the driver and these equipments to

short, damaging both.

CN5

Use a shielded cable for I/O signals.

Connector pin assignment

(viewed from soldering side)

1

2

17

18

19

20

35

36

•

Pin assignment

Operating mode

Name

Pin

No

Positioning

operation

Push-motion

operation

∗2

Positioning

operation

Push-motion

operation

∗2

1

−

−

2 GND

Ground

connection

3 ASG+

4 ASG

−

A-phase pulse output

(line driver)

5 BSG+

6 BSG

−

B-phase pulse output

(line driver)

7 TIM1+

8 TIM1

−

Timing output (line driver)

9 ALM+

10

ALM

−

Alarm output

11

WNG+

12

WNG

−

Warning output

13

END+

14

END

−

Positioning complete output

15

READY+/AL0+

∗1

16

READY

−

/AL0

−

∗1

Operation ready complete output/

Alarm code output 0

17

TLC+/AL1+

∗1

18

TLC

−

/AL1

−

∗1

Torque limit output/

Alarm code output 1

19

TIM2+/AL2+

∗1

20

TIM2

−

/AL2

−

∗1

Timing output (open collector)/

Alarm code output 2

21

GND Ground

connection

22

IN-COM Input

common

23

C-ON

Current on input

24

CLR/ALM-RST

Deviation clear input/

Alarm reset input

25

CCM

Current control mode ON input

26

CS

T-MODE

∗1∗2

Resolution

selection input

Push-motion

operation ON

27

−

M0

∗1∗2

−

28

RETURN

M1

∗1∗2

Return to

electrical home

operation

29

P-RESET

M2

∗1∗2

Position reset

input

Push-current

setting selection

input

30

FREE

Excitation OFF, electromagnetic

brake release

31

CW+/PLS+

32

CW

−

/PLS

−

CW pulse input/Pulse input

(+5 V or line driver)

33

CW+24 V/PLS+24 V

CW pulse input/Pulse input (+24 V)

34

CCW+24 V/DIR+24 V

CCW pulse input/Direction input

(+24 V)

35

CCW+/DIR+

36

CCW

−

/ DIR

−

CCW pulse input/Direction input

(+5 V or line driver)

∗1

The signal will become effective if the applicable setting has been

changed using the

OPX-2A

or

MEXE02

.

∗2

These signals are used to perform push-motion operation. Do not set

with the

DG

Ⅱ

Series. Refer to the USER MANUAL for details.

Note

•

The driver I/O signals of the

DG

Ⅱ

Series and

EAS

Series are in common with those of the

AR

Series,

but the signals are not compatible with the drivers of

other series.

Do not connect the I/O signals with pin

assignments of other series.

•

Do not perform push-motion operation or sensorless

return-to-home operation with the

DG

Ⅱ

Series.

Doing so may result in damage to the actuator.