3

z

Removing/Installing the gearhead

See the following steps to replace the gearhead or to change the cable position.

1.

Removing the gearhead

Remove the hexagonal socket head screws assembling the motor and

gearhead and detach the motor from the gearhead.

•

Assembly hexagonal socket head screw

Model

Screw size

Tightening

torque

BLM230

BLM460S

M2.6

0.4 N·m

(3.5 lb-in)

BLM5120

BLM6200S

BLM6400S

M3

0.6 N·m

(5.3 lb-in)

2.

Installing the gearhead

Using the pilot sections of the motor and gearhead as guides, install the

gearhead to the motor and tighten the hexagonal socket head screws.

Confirm that no gaps remain between the motor flange surface and the end

face of the gearhead pilot section.

At this time, the motor cable position can be changed to a desired 90°

direction. When installing the gearhead, slowly rotate it clockwise/

counterclockwise to prevent the pinion of the motor output shaft from

contacting the side panel or gear of the gearhead.

Install using pilot sections as guides

Change the cable position to

a desired 90° direction.

Note

•

Do not forcibly assemble the motor and gearhead. Also, do not

let metal objects or other foreign matter enter the gearhead.

The pinion of the motor output shaft or gear may be damaged,

resulting in noise or shorter service life.

•

Do not allow dust to attach to the pilot sections of the motor and

gearhead. Also, assemble the motor and gearhead carefully by

not pinching the O-ring at the motor pilot section. If the O-ring is

crushed or severed, grease may leak from the gearhead.

•

The hexagonal socket head screws assembling the motor and

gearhead are used to attach the motor and gearhead temporarily.

Be sure to use the supplied mounting screw set to install the motor.

■

■

Installing a load

When installing a load on the motor (gearhead), pay attention to the following

points.

•

Align the centerline of the motor output shaft (gearhead output shaft) with

the centerline of the load.

•

A key slot is provided on the output shaft of each combination type • parallel

shaft gearhead. Form a key slot on the load side and secure the load using the

supplied parallel key.

Note

•

When coupling the motor (gearhead) with a load, pay attention to

centering, belt tension, parallelism of pulleys, etc. Also, firmly secure

the tightening screws of the coupling or pulleys.

•

When installing a load, do not damage the motor output shaft

(gearhead output shaft) or bearing. Forcing in the load by driving

it with a hammer, etc., may break the bearing. Do not apply any

excessive force to the output shaft.

•

Do not modify or machine the motor (gearhead) output shaft. The

bearing may be damaged or motor (gearhead) may break.

When using the output shaft end tapped hole of a gearhead

(

GFV4G

,

GFV5G

,

GFV6G

only)

Use a tapped hole provided at the end of

the output shaft as an auxiliary means for

preventing the transfer mechanism from

disengaging.

Fixed screw

Screw

Spacer

Transmission

parts

Gearhead

model

Screw

size

Effective depth of

screw

GFV4G

No.10-

24UNC

10 mm (0.39 in.)

GFV5G

GFV6G

No.12-

24UNC

12 mm (0.47 in.)

■

■

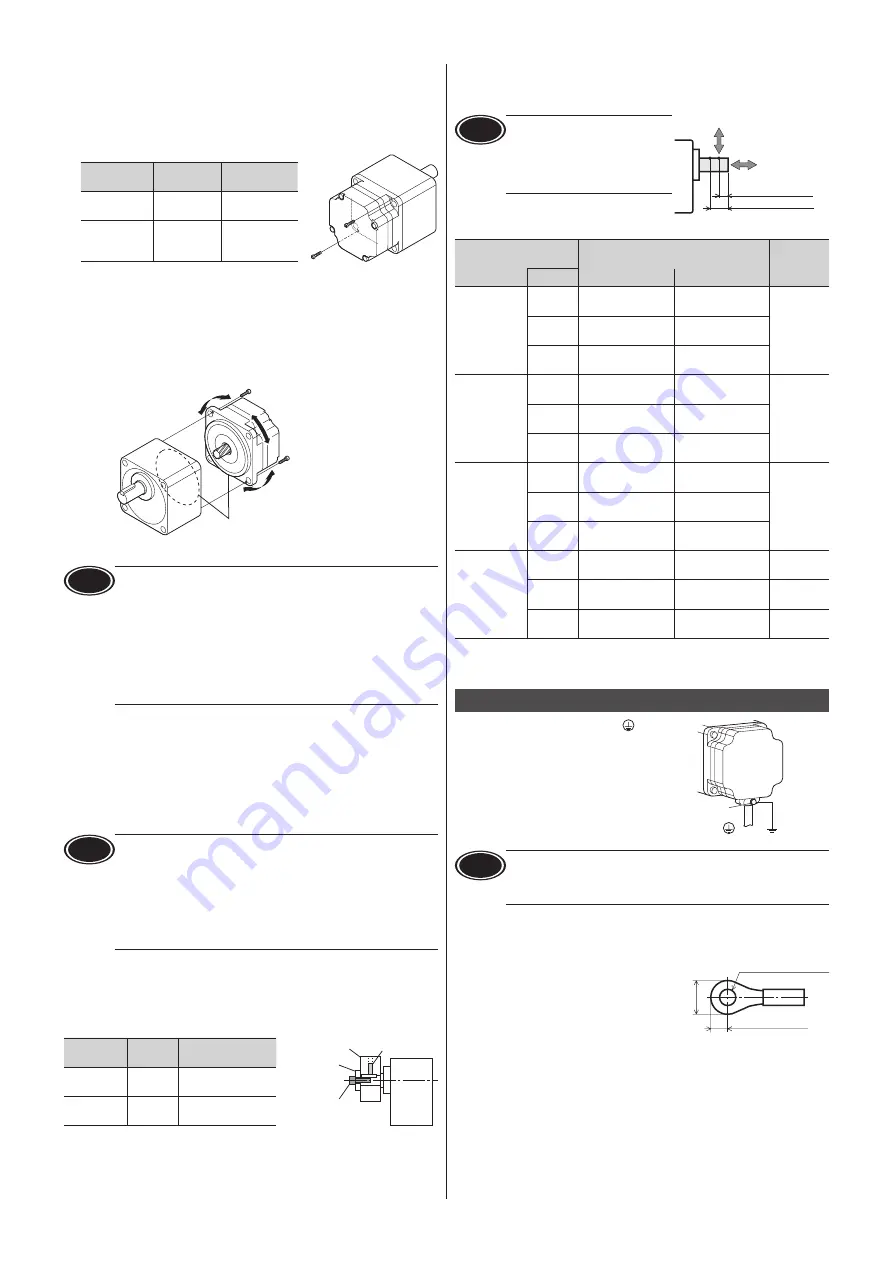

Permissible radial load and permissible axial load

The radial load and the axial load on the output shaft of the motor (gearhead)

must be kept under the permissible values listed below.

Note

Failure due to fatigue may occur

when the motor (gearhead)

bearings and output shaft are

subject to repeated loading by

a radial or axial load that is in

excess of the permissible limit.

10 mm (0.39 in.)

20 mm (0.79 in.)

Distance from output shaft end

Axial load

Radial load

Model

Permissible radial load [N (lb.)]

∗1

Distance from tip of gearhead output shaft

Permissible

axial load

[N (lb.)]

Gear ratio

10 mm (0.39 in.)

20 mm (0.79 in.)

BLM230

5

100 (22)

[90 (20)]

150 (33)

[110 (24)]

40 (9)

10

to

20

150 (33)

[130 (29)]

200 (45)

[170 (38)]

30

to

200

200 (45)

[180 (40)]

300 (67)

[230 (51)]

BLM460S

5

200 (45)

[180 (40)]

250 (56)

[220 (49)]

100 (22)

10

to

20

300 (67)

[270 (60)]

350 (78)

[330 (74)]

30

to

200

450 (101)

[420 (94)]

550 (123)

[500 (112)]

BLM5120

5

300 (67)

[230 (51)]

400 (90)

[300 (67)]

150 (33)

10

to

20

400 (90)

[370 (83)]

500 (112)

[430 (96)]

30

to

200

500 (112)

[450 (101)]

650 (146)

[550 (123)]

BLM6200S

BLM6400S

∗2

5

to

20

550 (123)

[500 (112)]

800 (180)

[700 (157)]

200 (45)

30

,

50

1000 (220)

[900 (200)]

1250 (280)

[1100 (240)]

300 (67)

100

,

200

1400 (310)

[1200 (270)]

1700 (380)

[1400 (310)]

400 (90)

∗1

The values assume a rated speed of 3000 r/min or below. The values in [ ] are based

on a rated speed of 4000 r/min.

∗2

The gear ratio of the

BLM6400S

is 5:1 to 50:1.

Grounding

Connect the Protective Earth Terminal

on the

motor to the ground near the motor.

Minimize the wiring length of the ground cable.

Protective

Earth

Terminal

Grounding

Note

Be sure to ground the motor and driver. Failure to do so may result

in electric shock or damage to the product.

Static electricity may cause damage to the product if the protective

earth terminals are not grounded.

■

■

Ground terminal

•

Applicable crimp terminal:

Round crimp terminal with insulation cover

•

Thread size of terminal: M4

•

Tightening torque: 1.2 N·m (10.6 lb-in)

•

Applicable lead wire:

AWG18 to 14 (0.75 to 2.0 mm

2

)

[mm (in.)]

4.8 (0.19) or less

9.5 (0.37) or less

Ø4.1 (0.16) or more

■

■

Precautions about static electricity

Static electricity may cause the driver to malfunction or suffer damaged.

Be sure to ground the motor and driver to prevent them from being damaged

by static electricity.